Quality Assurance

Efficient Factory, Focused on Smart Manufacturing

Jiangyin Gwing Technology relies on automated production lines and a professional technical team, specializing in the field of polymer composite materials. Using precision vacuum cooling, online film lamination, and other processes, the company produces cable trays, moisture-resistant resin doors, and weather-resistant windowsill boards. With stable quality and customized services, Gwing serves industries such as architectural decoration and electrical engineering. Choosing Gwing means choosing the golden triangle of technology, efficiency, and quality!

Scalable Production Capacity

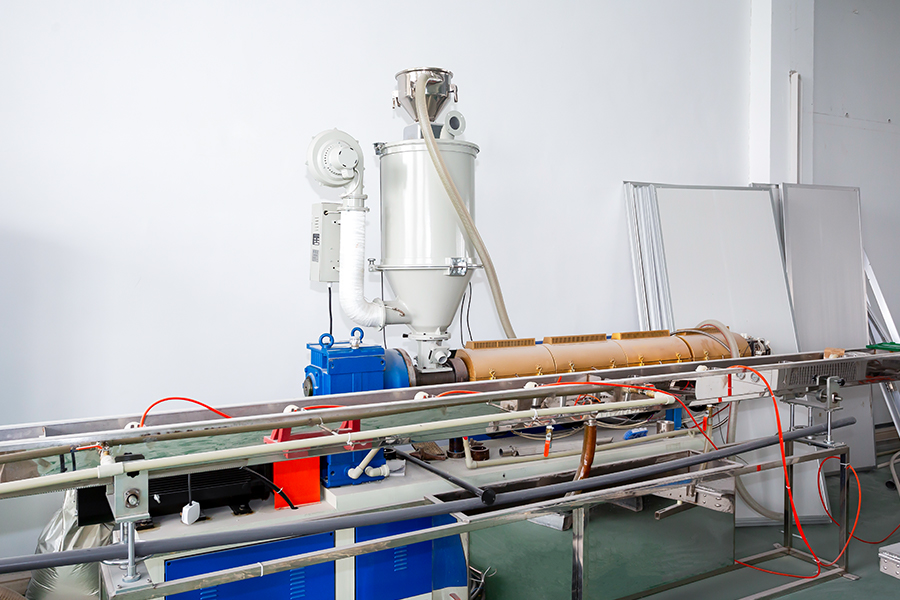

The factory covers an area of 6,000 square meters and is equipped with 32 fully automatic extrusion lines (including 10 extruders of 65, 2 extruders of 80 and 20 extruders of 51). (including 10 65 extruders, 2 80 extruders and 20 51 extruders), which can meet the efficient continuous production of PVC, WPC and other materials. Relying on the combination of multiple models, it realizes the integrated operation from mixing, extruding, cooling and shaping to cutting.

End-to-End Technical Strength

Cable Tray Production Process

1.Material Preparation & Extrusion:

Material mixing → PVC extrusion → Vacuum tank cooling and shaping → Cutting to required length

2.Post-Assembly Processing:

Precision cutting according to customer specifications Final assembly using adhesive bonding and screw fixation techniques

WPC Door Production Process

1.Material Preparation & Extrusion:

Material mixing → WPC extrusion → Vacuum tank cooling and shaping → Cutting to blank size

2.Surface Lamination:

Application of decorative layers (e.g., wood grain film) using flat laminating technology

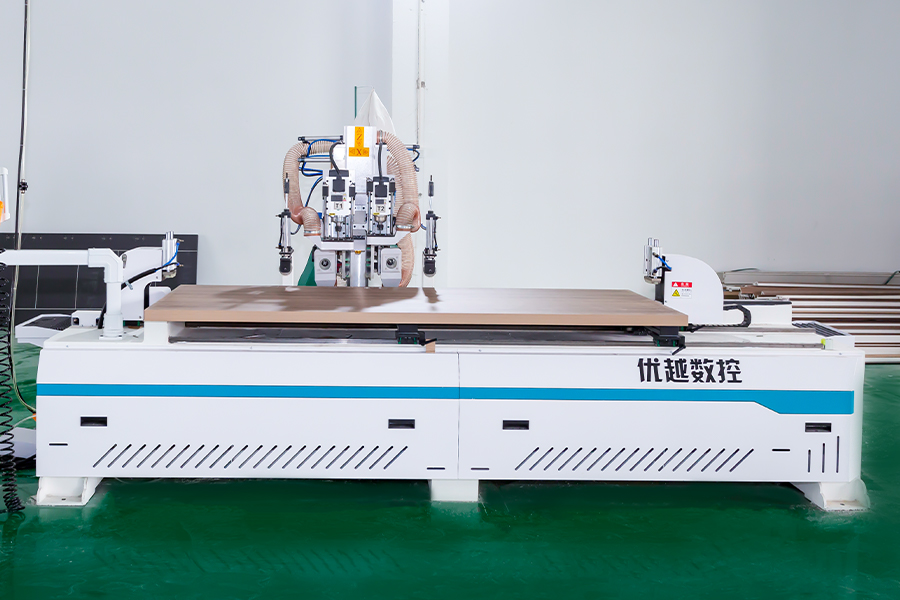

3.Precision Quad-Cutting:

Computer-controlled four-sided cutting for dimensional accuracy

4.PUR Hot Melt Edge Banding:

Automated edge sealing with PUR reactive hot melt adhesive

5.CNC Lock Hole Machining:

Manufacturing Process of UPVC Window Sill

Material Mixing and Extrusion

Combine materials → Extrude PVC → Cool and shape the extrudate in a vacuum water tank → Apply cladding film on - line → Cut to the desired size

Technical Quality Control Assurance

A professional team consisting of 20 core technical personnel closely monitors the entire production process, providing process optimization and real-time problem-solving solutions. The company implements a strict quality control system, starting with the density and melt index testing of raw materials upon arrival, real-time monitoring of extrusion thickness and cooling rate during production, and comprehensive inspection control at the finished product stage. This ensures that dimensional tolerances, compressive strength, and edge sealing meet the required standards, helping to reduce the return rate of export products.

Factory Show

Achieve every whimsy