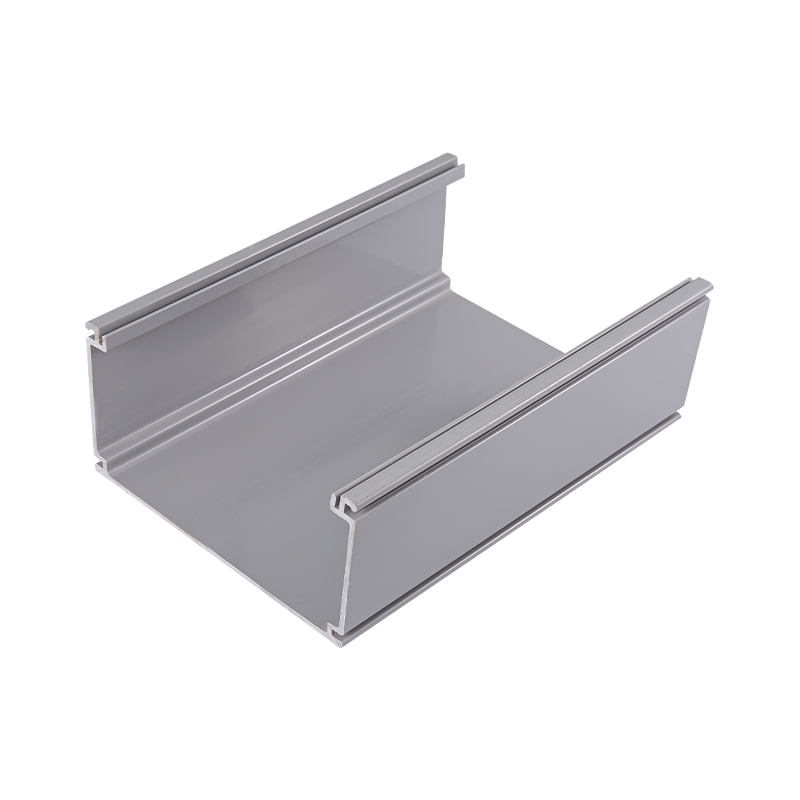

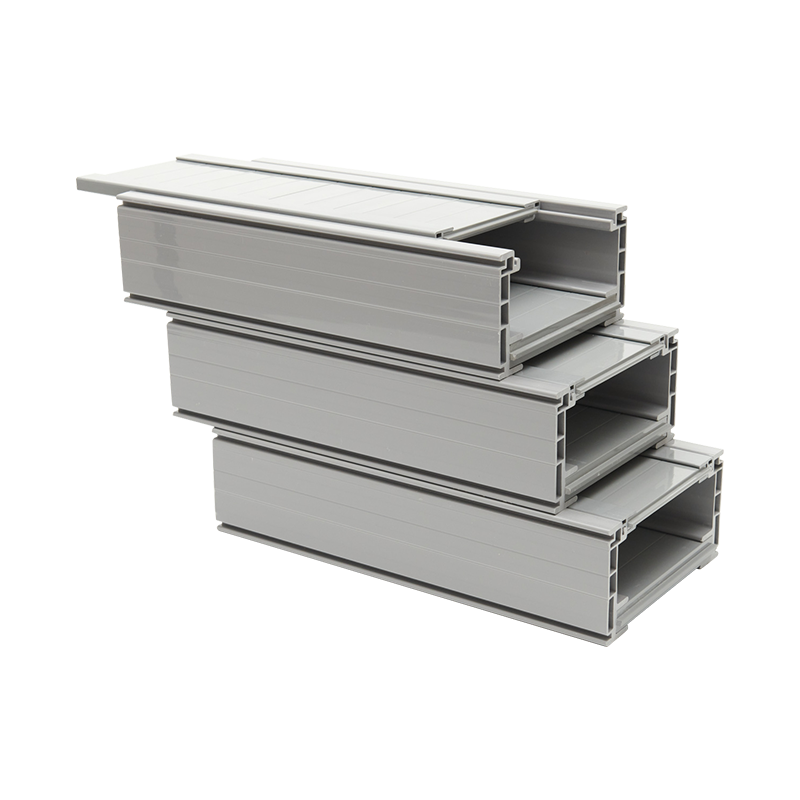

Why is UPVC cable tray the first choice for modern projects?

In modern engineering construction, the safety and durability of cable laying are crucial, and cable trays are key equipment for supporting and protecting cables. The material selection directly affects the stable operation of the entire power system. As an emerging composite material product, UPVC cable trays are gradually replacing traditional metal trays and becoming the first choice for many projects. So, what advantages do they have to gain such favor?

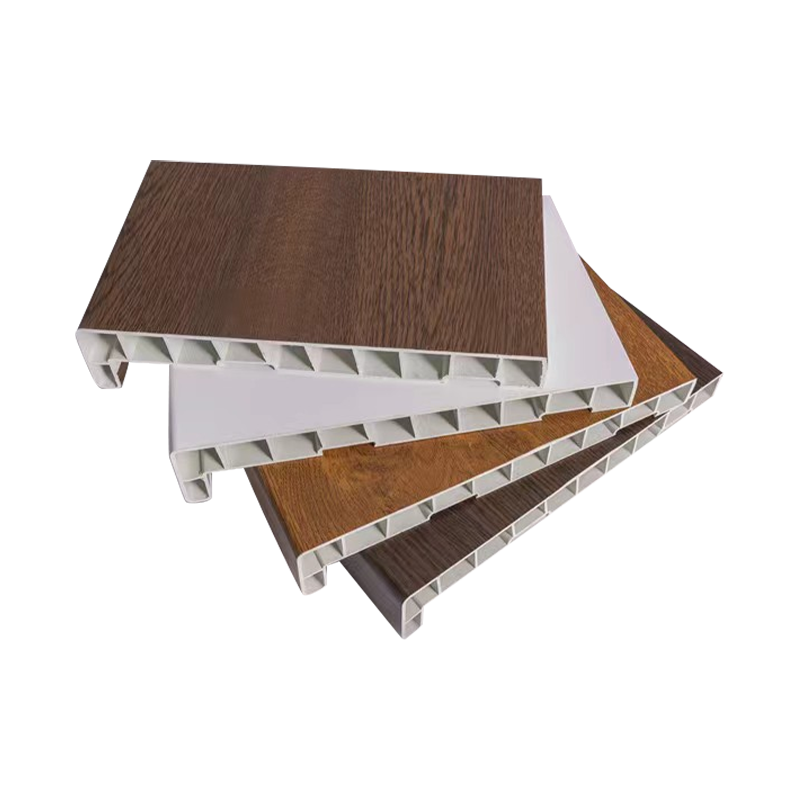

Excellent corrosion resistance, adaptable to complex environments

Traditional metal trays are prone to rust in harsh environments such as humidity, acid and alkali, which not only affects the service life, but also may cause damage to the cable insulation layer, causing safety hazards. UPVC cable trays use polyvinyl chloride as the main raw material and have extremely strong corrosion resistance. Whether in the acid and alkali workshop of a chemical company or in the high humidity environment of coastal areas, they can maintain stable performance and effectively avoid the maintenance difficulties caused by rust.

Jiangyin Gwing Technology Co., Ltd., as a technology-driven enterprise that has been deeply involved in the PVC/WPC material industry for nearly 20 years, has fully utilized its technical accumulation in the field of polymer composite materials in the production of UPVC cable trays. The UPVC cable trays it produces have been treated with special processes to further improve the acid, alkali and salt spray resistance of the material. Even in an environment with long-term contact with corrosive media, the structure can still be ensured to be intact and provide reliable protection for the cables.

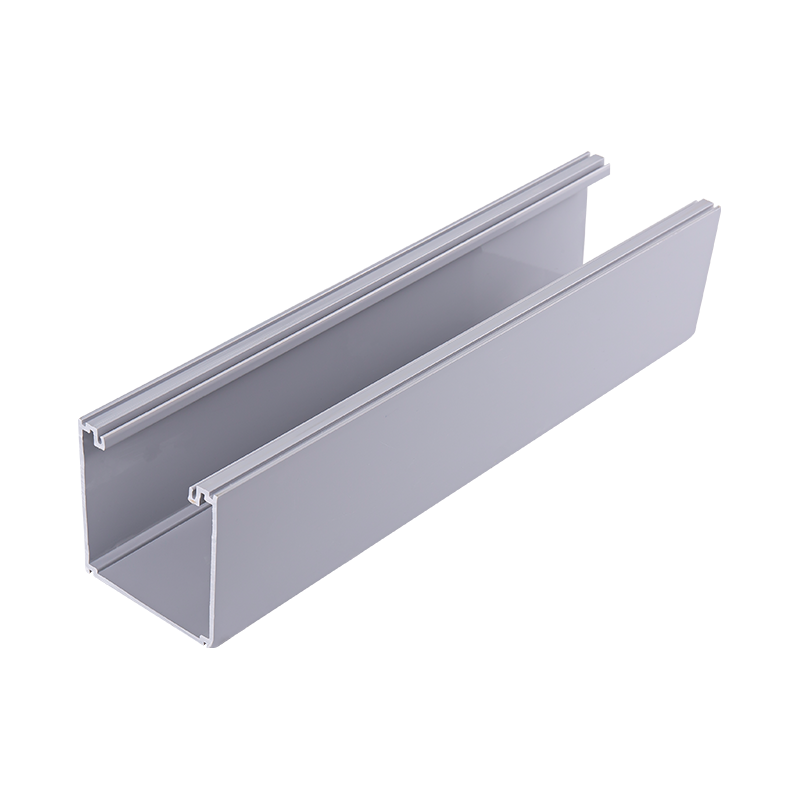

Lightweight and high strength, reducing construction and transportation costs

Compared with metal cable trays, UPVC cable trays are lighter, which brings many conveniences to engineering construction. During transportation, the lighter weight can reduce the load of the transport vehicle and reduce transportation costs; during the installation process, no large lifting equipment is required, and manual labor can easily carry and install, which not only improves construction efficiency, but also reduces safety risks during construction.

At the same time, UPVC materials have high strength and can meet the load-bearing requirements during cable laying. Jiangyin Gwing Technology Co., Ltd. optimizes material formula and production process through continuous technical research and development, so that its UPVC cable trays can maintain lightweight characteristics while reaching or even exceeding the standards of some metal cable trays, and can fully meet the use requirements of various engineering scenarios.

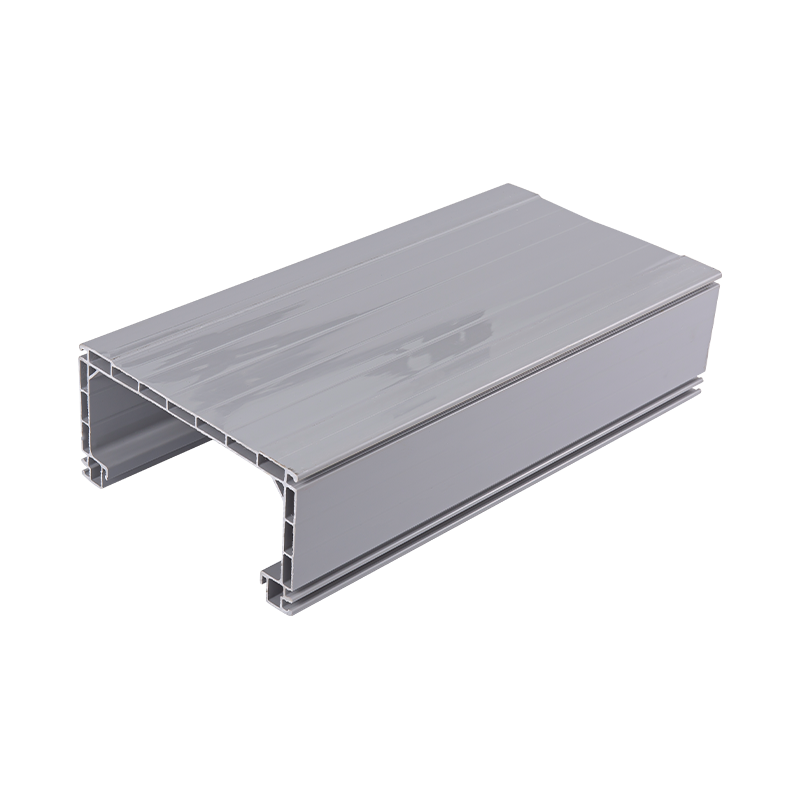

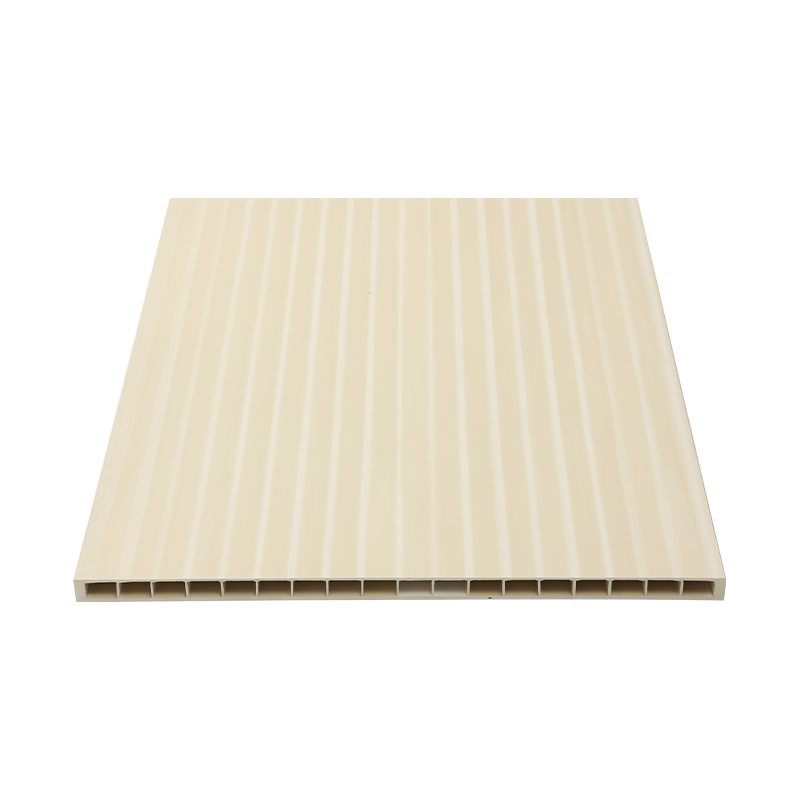

Excellent insulation performance to ensure electricity safety

The safe operation of the power system is inseparable from good insulation protection. UPVC material itself has excellent insulation performance. The cable tray made of it will not conduct electricity, which can effectively avoid electric shock accidents caused by the cable tray being electrified. UPVC cable trays can also reduce electromagnetic interference. For some places with high requirements for electromagnetic environment, such as precision instrument workshops and communication rooms, it is an ideal choice.

Jiangyin Gwing Technology Co., Ltd. always adheres to the concept of environmental protection. When producing UPVC cable trays, it strictly controls the quality of raw materials to ensure that the products do not contain harmful substances and have stable insulation performance. Its products have been tested many times, and indicators such as insulation resistance meet relevant national standards, providing a strong guarantee for the safe operation of the power system.

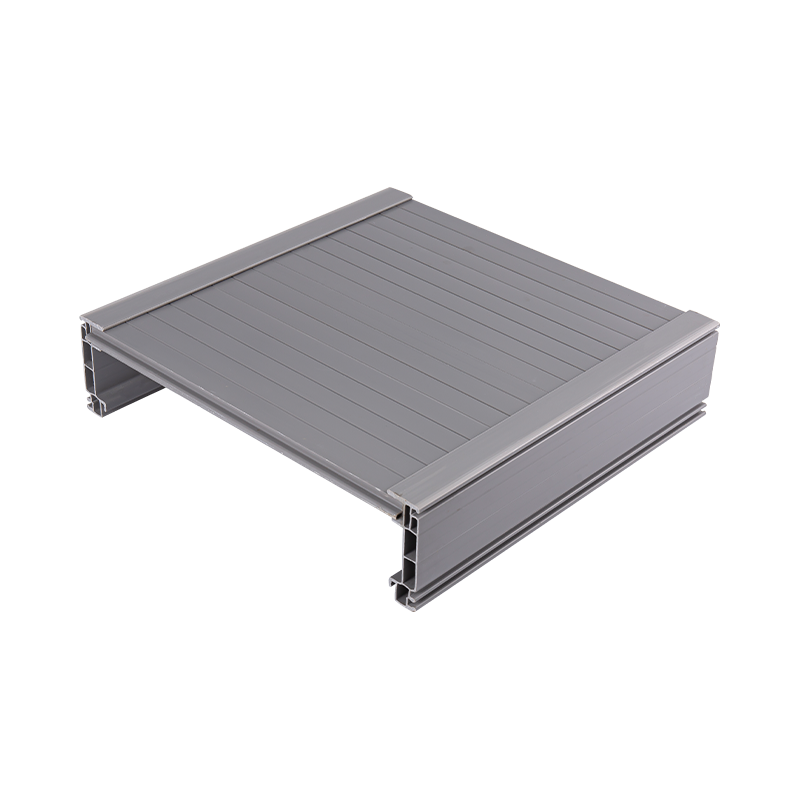

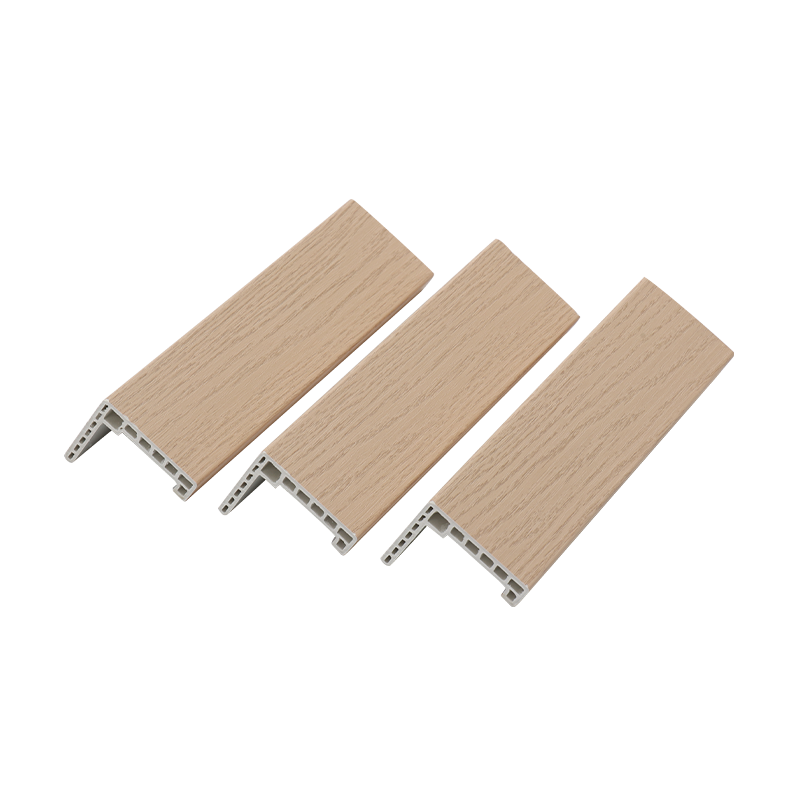

Good flame retardancy, improve fire safety level

Fire is a major safety threat faced in engineering construction. The flame retardancy of cable trays is directly related to the speed of fire spread when a fire occurs. UPVC cable trays have good flame retardancy. When encountering open flames, their burning speed is slow, and they can quickly extinguish themselves after leaving the fire source, which can effectively delay the spread of fire and buy precious time for personnel evacuation and fire fighting and rescue.

Jiangyin Gwing Technology Co., Ltd. takes flame retardancy as an important indicator in the process of product development. By adding high-efficiency flame retardants and other methods, UPVC cable trays can reach the flame retardancy level specified by the state. In practical applications, it can effectively reduce the risk of fire and improve the fire safety level of the project.

UPVC cable trays occupy an important position in modern engineering with many advantages such as strong corrosion resistance, light weight and high strength, excellent insulation performance, and good flame retardancy. It is believed that with the continuous development of polymer composite material technology, UPVC cable trays will play an important role in more fields and contribute to the safety and efficiency of engineering construction.

English

English

English

English عربى

عربى Español

Español