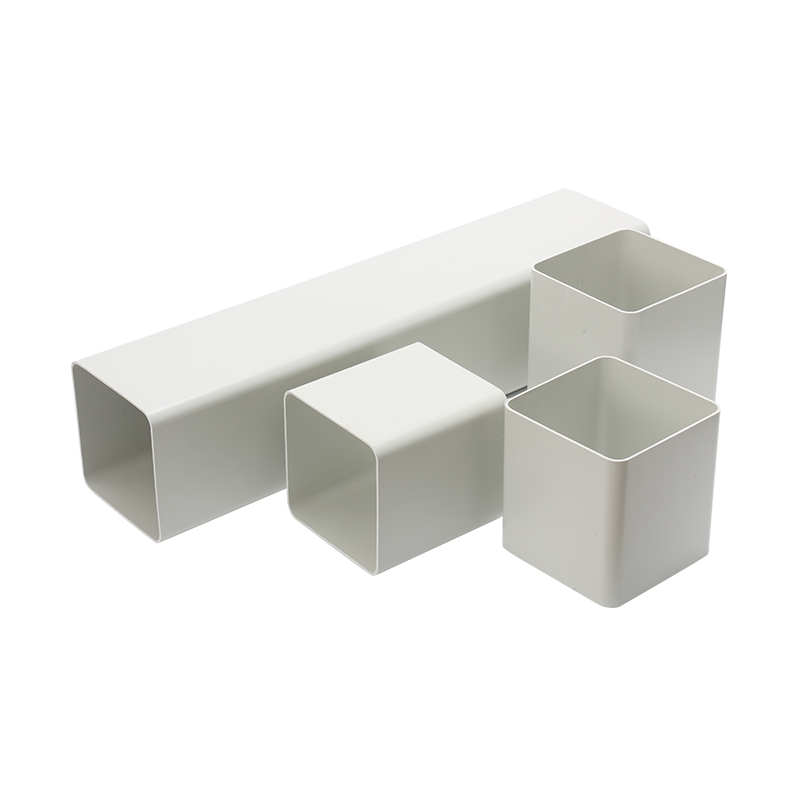

Why has UPVC Square Pipe become the preferred material for modern engineering?

In many engineering fields such as construction, municipal administration, and agriculture, the choice of materials directly affects the quality, life, and cost of the project. In recent years, UPVC Square Pipe has gradually become a popular choice to replace traditional metal pipes and concrete pipes with its unique performance advantages. What kind of technical strength does this seemingly ordinary plastic pipe have to stand out in the fierce material competition?

1. The core performance advantages of UPVC Square Pipe

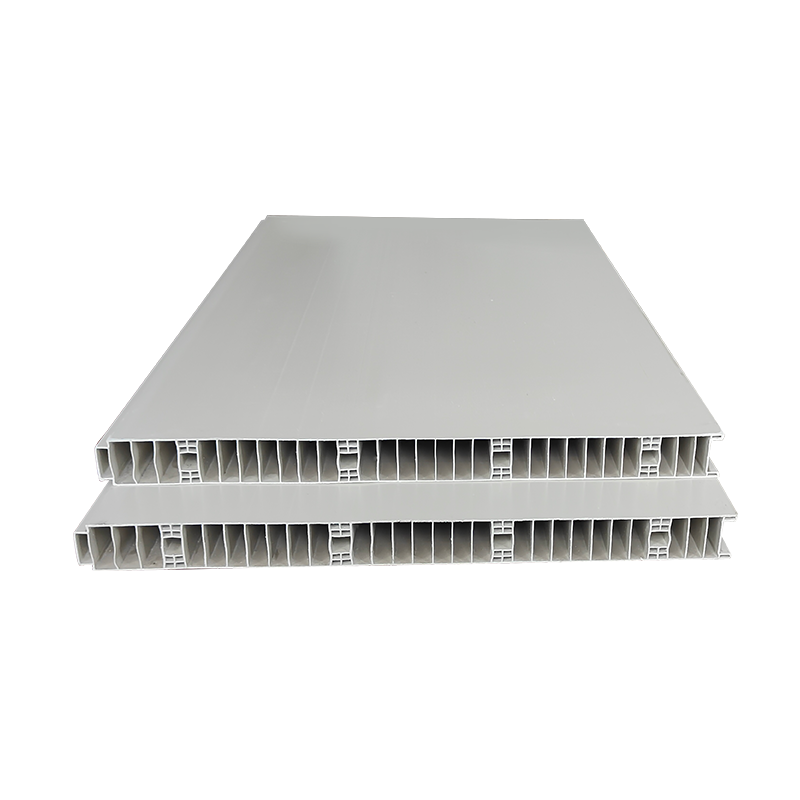

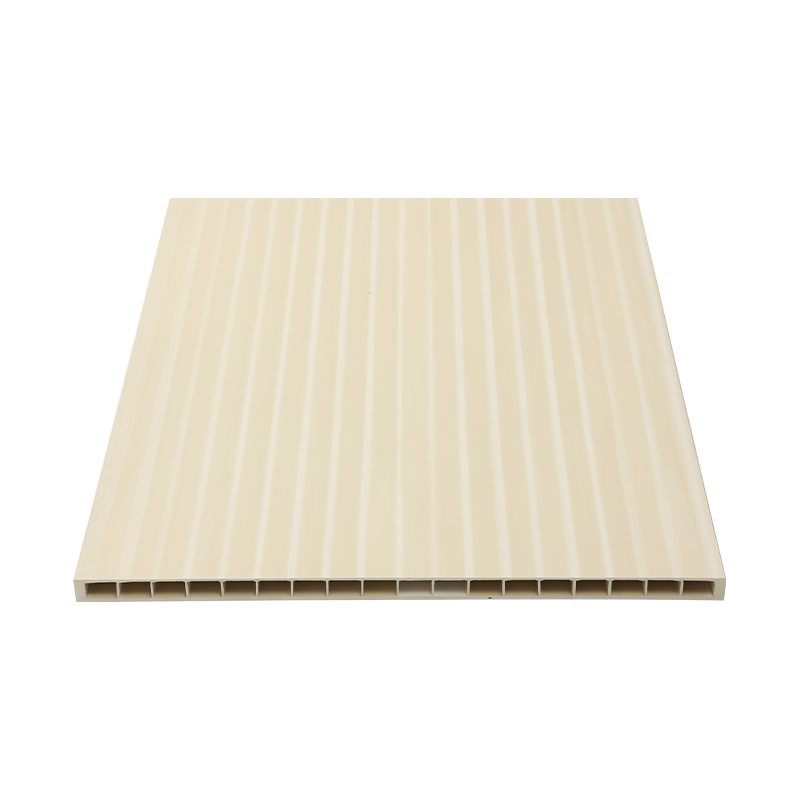

UPVC Square Pipe is made of polyvinyl chloride resin as the main raw material, and is extruded and molded by adding stabilizers, lubricants and other additives. Compared with traditional pipes, its core advantages are reflected in three aspects:

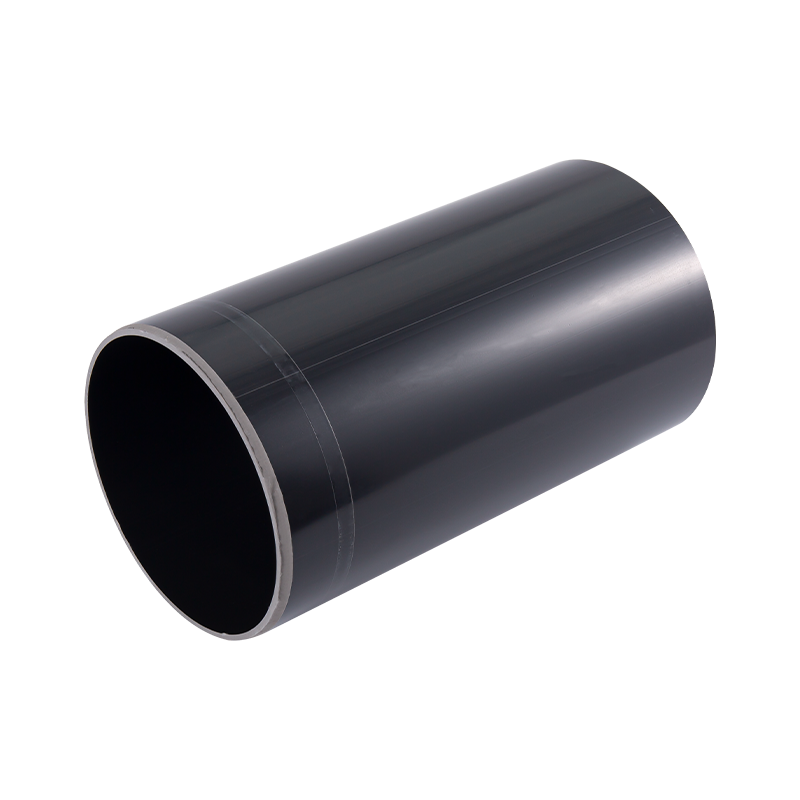

The first is excellent corrosion resistance. Metal pipes are easily corroded by acids and alkalis, while concrete pipes face the problems of weathering and chemical corrosion. UPVC square pipes have strong resistance to most chemical substances, especially suitable for conveying media containing acids, alkalis, and salts, and perform outstandingly in scenes such as chemical sewage discharge and electroplating wastewater treatment.

The second is the physical properties of light weight and high strength. The density of UPVC material is only 1/5 of that of steel. No heavy lifting equipment is required during installation, which can greatly reduce construction intensity and labor costs. At the same time, the impact strength of UPVC square pipes processed by special technology reaches more than 10kJ/m², which can withstand soil pressure and external loads and meet the engineering requirements of underground laying.

Finally, it has excellent cost performance. The raw material cost of UPVC square pipes is lower than that of stainless steel and copper, and the energy consumption of the production process is only 1/8 of that of steel smelting. More importantly, its service life can reach more than 50 years, with almost no maintenance required during this period, and the full life cycle cost is much lower than that of traditional pipes.

2. Expansion of application scenarios in multiple fields

The rectangular cross-section design of UPVC Square Pipe gives it a unique advantage in space utilization. It has been widely used in three major fields:

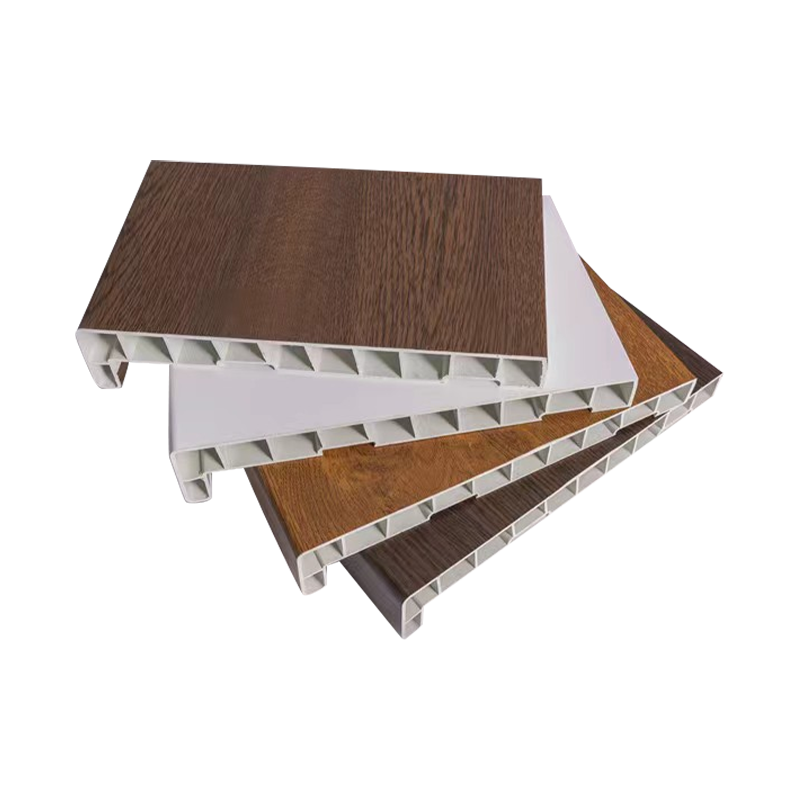

In construction projects, UPVC square pipes are used as rainwater pipes, air conditioning condensate pipes and cable protection pipes, which can not only avoid the rust problem of metal pipes, but also achieve rapid installation through snap-on connections. After a high-rise residential project used UPVC square tubes to replace traditional cast iron rainwater pipes, the construction efficiency increased by 40%, and there was no pipe blockage or leakage in ten years.

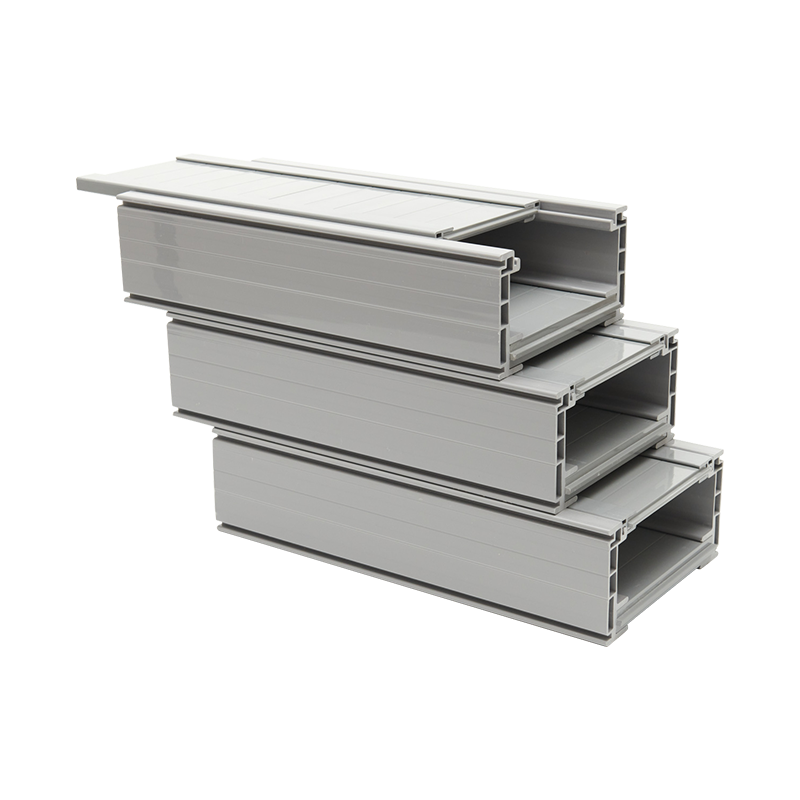

The value of UPVC square tubes can be better reflected in the field of municipal construction. In the urban underground integrated pipe gallery project, UPVC square tubes are used to store communication optical cables and power cables, and their insulation performance can effectively reduce the risk of short circuits; in the sidewalk paving project, they are used as seepage square tubes to form a rainwater collection system to realize the ecological concept of sponge cities.

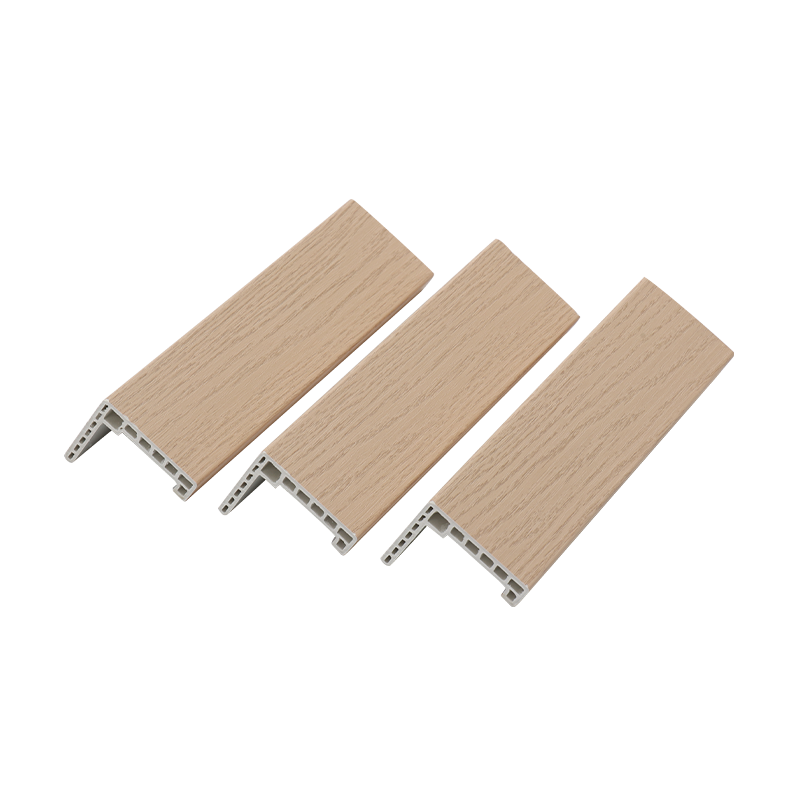

The application of UPVC square tubes in agriculture and aquaculture highlights its environmental protection characteristics. The greenhouse bracket built with UPVC square tubes has excellent anti-ultraviolet aging performance and can withstand extreme climates; in aquaculture, as oxygen pipelines and sewage pipelines, their non-toxic and odorless characteristics will not pollute the water body and meet the green aquaculture standards.

III. Technical practice of industry benchmarks

In the field of UPVC material application, Jiangyin Gwing Technology Co., Ltd.'s technical accumulation is quite representative. As a technology-based enterprise that has been deeply involved in the PVC/WPC material industry for nearly 20 years, Jiangyin Gwing Technology Co., Ltd. has always taken environmental protection as its core and continuously made breakthroughs in the modification technology of UPVC square tubes.

Through formula optimization, the impact strength of UPVC square tubes produced by Jiangyin Gwing Technology Co., Ltd. has increased by 20%, while maintaining a nominal pressure level of 1.6MPa; the use of low-temperature extrusion technology not only reduces energy consumption by 30%, but also reduces the emission of harmful substances. The UV-resistant UPVC square tubes developed by it have been verified by accelerated aging tests that their service life can be extended to more than 60 years, and have been successfully applied in photovoltaic power station cable protection projects in high-altitude areas.

This technical practice confirms the development potential of UPVC square tubes

- through continuous material innovation, the application boundaries are continuously expanded. From ordinary drainage to high-pressure transmission, from ground installation to deep-sea laying, UPVC square tubes are rewriting the selection standards of engineering materials with strength.

When we examine the technological evolution and application results of UPVC Square Pipe, it is not difficult to find that the key to its success lies in the ultimate exploration of material properties and the precise response to market demand. Today, when green development has become a global consensus, UPVC square pipes, which have both environmental performance and engineering value, will undoubtedly write a new chapter for plastic pipes in more fields.

English

English

English

English عربى

عربى Español

Español