Why can WPC door panel be widely used in home and commercial fields?

Superior performance: WPC door panels have the advantages of both wood and plastic, with excellent waterproof and moisture-proof performance, and are not easy to deform, mold, or rot due to moisture. The WPC door panels produced by Jiangyin Gwing Technology Co., Ltd., with high-quality raw materials and advanced technology, can effectively resist water erosion. They are especially suitable for use in humid environments such as kitchens and bathrooms, and can maintain good condition for a long time in bathrooms in commercial places or home kitchens.

Environmental protection and health: No harmful substances are added during its production process, which meets national environmental protection standards and is harmless to human health. It is an ideal decorative material for modern homes and commercial spaces that focus on environmental protection. Jiangyin Gwing Technology Co., Ltd. focuses on the field of polymer composite materials, and the WPC door panels it produces strictly follow environmental protection standards to provide safety protection for home and commercial environments.

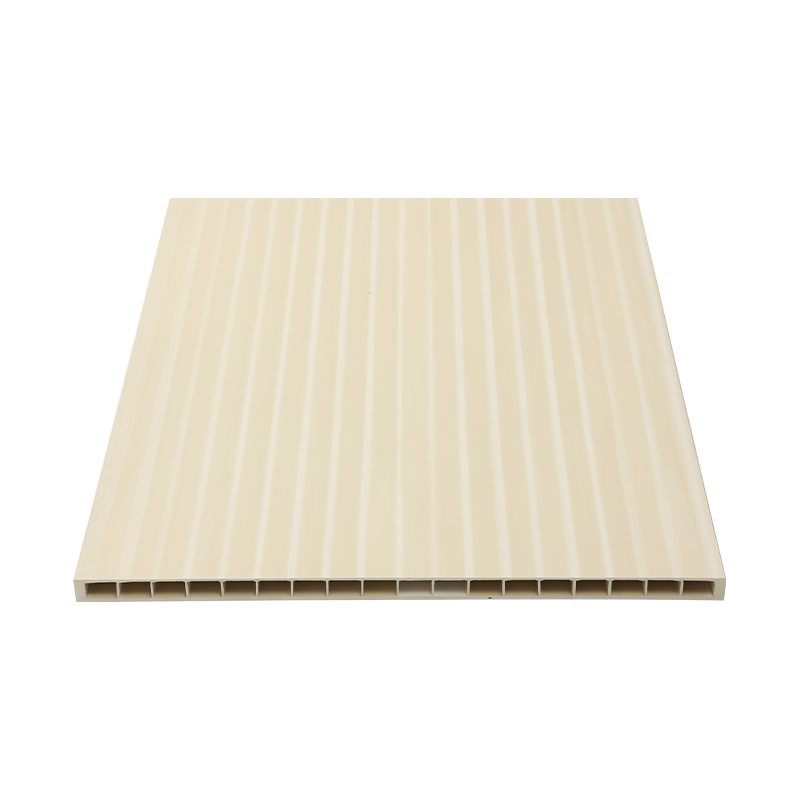

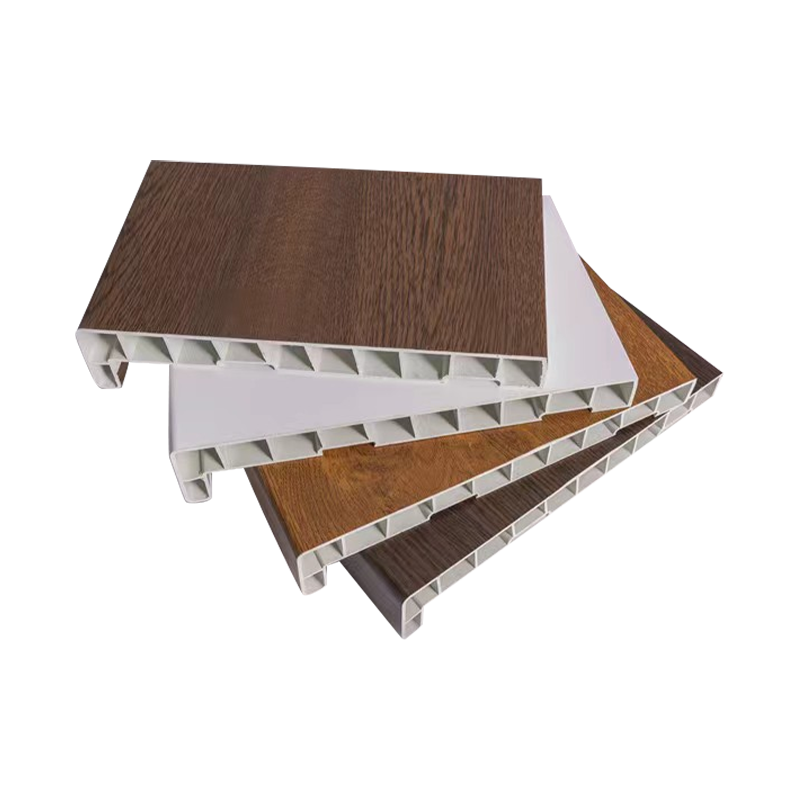

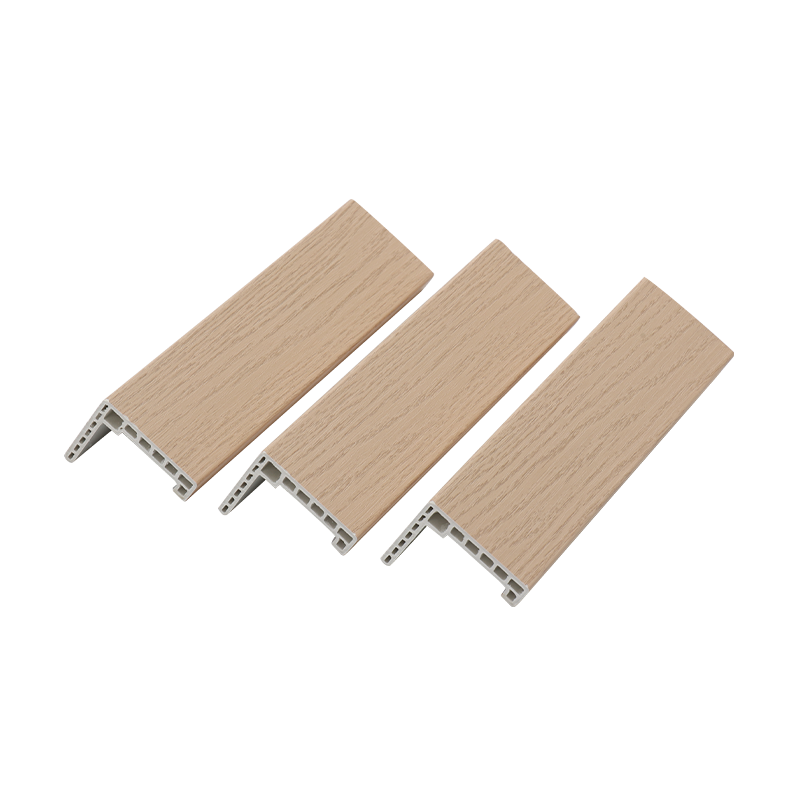

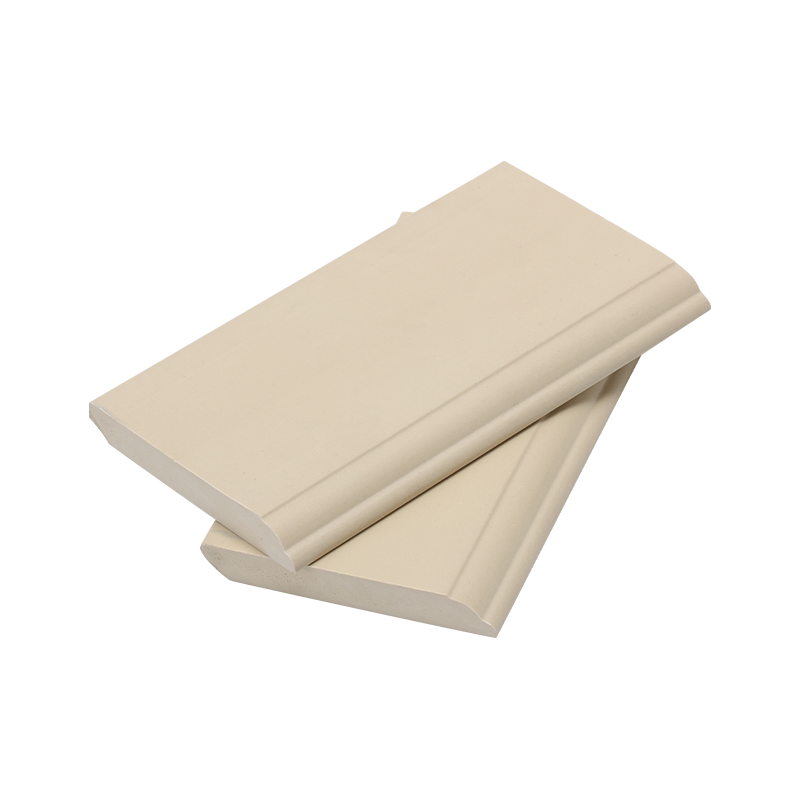

Beautiful appearance: Through surface treatment technology, WPC door panels can simulate the texture and color of a variety of woods, with realistic wood grain effects, smooth surface, comfortable touch, rich colors and not easy to fade, which can meet the needs of different decoration styles, whether it is personalized decoration of home or unified style of commercial places, it can be well adapted.

What are the unique features of the raw materials of WPC door panels?

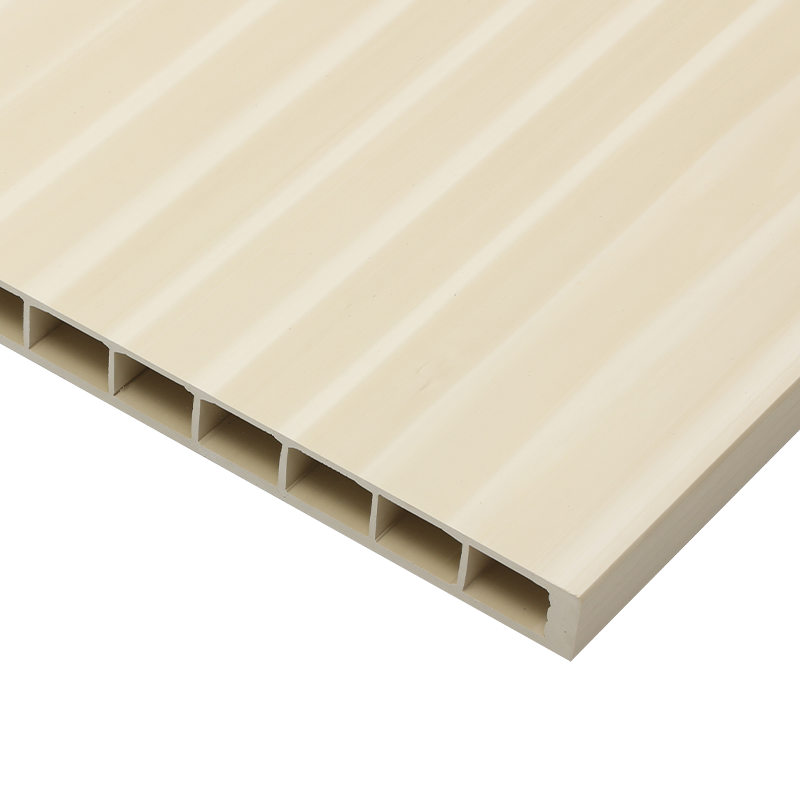

PVC resin is an important component of WPC door panels. It gives door panels good processing properties, so that door panels can be made into various shapes and sizes through processes such as extrusion molding or compression molding. At the same time, PVC resin also has excellent waterproof and moisture-proof properties, which is one of the key factors for WPC door panels to be used in humid environments. The addition of wood powder gives the door panels the texture and some properties of natural wood, such as certain thermal insulation properties and certain strength. In addition, after the wood powder is mixed with PVC resin, etc., it is treated with a special process to make the door panels present a realistic wood grain effect. Additives play an important role in WPC door panels. They can improve the weather resistance of the material, make the door panels less prone to aging and fading under different environmental conditions, and enhance the flame retardancy of the material, improve the fire safety performance of the door panels, and make WPC door panels more suitable for use in a variety of places.

How does the production process of WPC door panels ensure its quality?

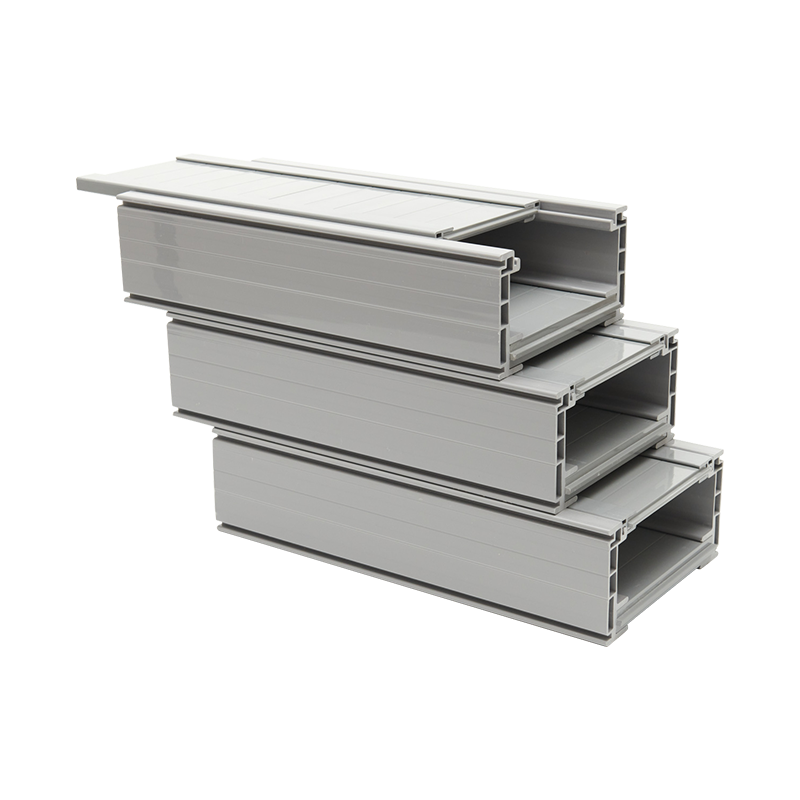

When Jiangyin Gwing Technology Co., Ltd. produces WPC door panels, it will mix PVC resin, wood powder and various additives in a strict proportion. Accurate proportions are the basis for ensuring the stable performance of door panels. Only by mixing evenly can the characteristics of various raw materials be fully utilized, so that the door panels have good waterproof and wear-resistant properties. Extrusion molding or compression molding is usually used. After heating and plasticization, the mixture is molded in a mold. The precision of the mold determines the size accuracy and shape accuracy of the door panel. The company uses advanced mold technology to ensure that the size of the door panel meets the standard and the shape is regular, providing a good foundation for subsequent use. The molded door panel undergoes cooling, trimming and other processes. The cooling process can make the structure of the door panel more stable, and trimming can remove excess scraps, making the surface of the door panel smooth and the edges neat, which is not only beautiful, but also reduces safety hazards during use, and also helps with subsequent installation and other operations.

What are the advantages of WPC door panels in different environments?

Home environment: In the home, WPC door panels can be used for interior doors. Their rich colors and textures can meet the needs of different home decoration styles and create a warm and comfortable living atmosphere. Moreover, their environmentally friendly and healthy characteristics can provide a safe living environment for the family. At the same time, the characteristics of easy processing and installation make home decoration more convenient and can effectively shorten the decoration period.

Public places: For public places such as schools, hospitals, hotels, and guesthouses, the waterproof, moisture-proof, mildew-proof, and insect-proof properties of WPC door panels are particularly important, which can ensure environmental safety and hygiene and reduce maintenance costs. Its good sound insulation performance can also provide a relatively quiet environment for public places. For example, the use of WPC door panels in hospital wards can reduce external noise interference and is conducive to patient rest.

Special environment: In special environments such as bathrooms and storage rooms with large temperature differences, humidity, and poor ventilation, WPC door panels can effectively prevent moisture and corrosion and extend their service life. The WPC door panels produced by Jiangyin Gwing Technology Co., Ltd., with their excellent moisture-proof performance, are not easy to deform or rot even in long-term humid bathrooms, and can maintain good use status.

WPC door panels are made of wood-plastic composite materials (WPC for short), which have the advantages of both wood and plastic and are widely used in home and commercial fields.

Product Introduction

Raw materials: Mainly composed of PVC resin, wood powder and various additives. PVC resin gives it good processing performance and waterproof and moisture-proof properties, while additives are used to improve the weather resistance and flame retardancy of the material.

Production process: Usually manufactured by extrusion molding or compression molding. First, the raw materials are mixed evenly in a certain proportion, heated and plasticized, and then formed in a mold, and then cooled, trimmed and other processes are performed to finally make a door panel with a specific shape and size.

Appearance and texture: WPC door panels can simulate the texture and color of various woods, such as oak, walnut, cherry, etc., through surface treatment technology, with realistic wood grain effect, smooth surface, comfortable touch, and can meet the personalized needs of different consumers for the appearance of door panels.

English

English

English

English عربى

عربى Español

Español