A new door frame that combines environmental protection, durability and convenience

WPC door frame uses wood fiber as a natural material, which is the basis of its environmental protection. Wood fiber itself comes from nature and has little negative impact on the environment throughout its life cycle. In addition, no harmful chemicals such as formaldehyde are added during the production process. WPC door frame eliminates this hidden danger from the source, meets national environmental protection standards, and creates a safe and healthy living and working environment for users. Jiangyin Gwing Technology Co., Ltd. has strict quality control in this regard. Relying on automated production lines, the company strictly screens materials such as wood fiber in the procurement of raw materials to ensure their natural purity. During the production process, a professional technical team uses advanced technology to ensure that no harmful chemicals are introduced into the entire production process. From raw materials to finished products, each process is strictly tested to ensure that the environmental performance of the product meets or even exceeds national standards, so that consumers can use it with more confidence.

WPC door frame is sturdy and durable in what aspects?

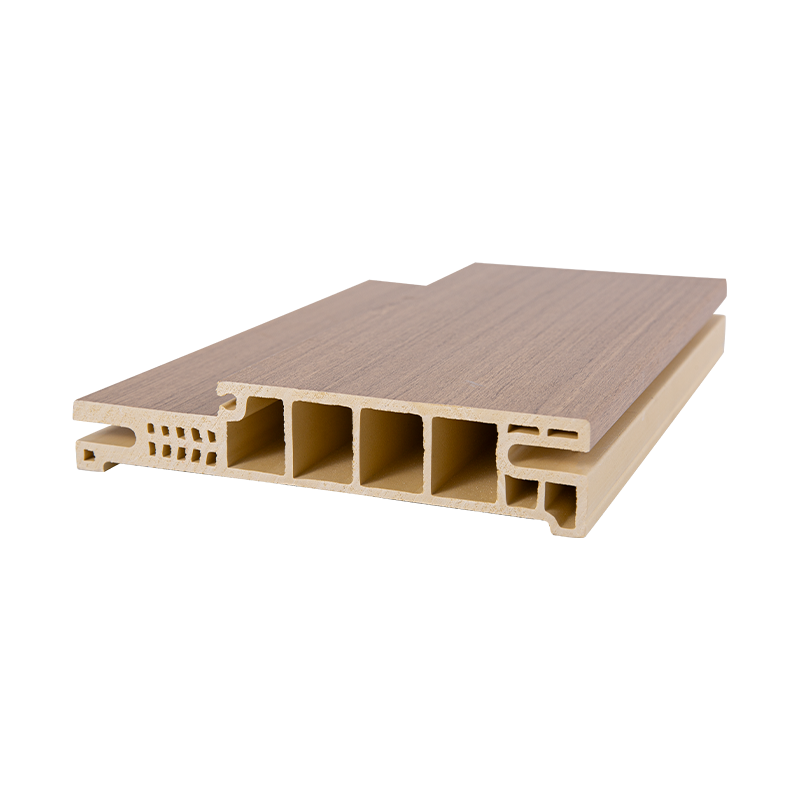

WPC door frame has high hardness and strength, which makes it perform well in daily use. It can easily bear the weight of the door. Whether it is an indoor door that is frequently opened and closed, or an outdoor door that is subjected to a certain external force, the WPC door frame can stably support it and is not prone to cracking, deformation and other problems. It also has good wear resistance and scratch resistance. In a family home, daily furniture handling and the touch of cleaning tools may cause wear and tear on the door frame, and the WPC door frame can effectively resist these situations and maintain the beauty of the surface for a long time. In commercial and office places, there is a large flow of personnel, and the door frame is subjected to more tests. The sturdy and durable characteristics of the WPC door frame enable it to adapt to this high-intensity use environment and greatly extend its service life. Jiangyin Gwing Technology Co., Ltd. focuses on the field of polymer composite materials, and its WPC door frame has obvious advantages in sturdiness and durability. The company adopts precision vacuum cooling, online lamination and other processes. These advanced processes make the door frame structure more stable and the combination between materials more compact. Produced through an automated production line, the consistency and stability of product quality are guaranteed. Compared with some similar products on the market, Jiangyin Gwing Technology Co., Ltd.'s WPC door frame performs better in hardness and strength tests, can withstand greater external impact, and has excellent wear and scratch resistance during long-term use, reducing the cost and trouble of replacing door frames for users.

Why is WPC door frame insect-proof, and what are its advantages over traditional wooden door frames?

Traditional wooden door frames are usually made of natural wood, which is easily targeted by insects and ants. Insects and ants will eat into the wood, destroy the structure of the door frame, and cause problems such as hollows and fragility in the door frame, seriously affecting its service life and safety. WPC door frame is different. It is mainly composed of resin, wood fiber and other additives. Among them, the structure formed by resin materials is not attractive to insects and ants, and wood fibers are not easily eaten by insects and ants after special treatment. This material property fundamentally eliminates the possibility of insect ant erosion, and there is no need to worry about the door frame structure being damaged by insects. Compared with traditional wooden door frames, the insect-proof advantage of WPC door frame reduces a lot of maintenance costs. Once the traditional wooden door frame is infested with insects, it needs to be treated with drugs, repaired and other maintenance work, which not only takes time and money, but also may not be ideal. Since WPC door frames are not infested by insects and ants,

How is the easy installation feature of WPC door frames reflected, and what impact does it have on construction efficiency?

WPC door frames are relatively light, which makes them more convenient during transportation. At the construction site, workers can easily carry the door frame to the designated location, reducing manpower consumption and transportation difficulty. Moreover, its dimensional accuracy is high. During the production process, the dimensional accuracy of the door frame is guaranteed by advanced equipment and processes. During installation, it can fit closely with the wall, reducing the adjustment time during the installation process. The installation process is also relatively simple, without the need for complex tools and techniques, and ordinary construction workers can operate proficiently after simple training. For the construction team, the easy installation feature of WPC door frames can effectively improve construction efficiency. In the decoration of family houses, the door frame installation work can be completed faster, which can save more time for subsequent wall decoration, door installation and other processes, and speed up the progress of the entire decoration. In the decoration of commercial and office places, due to the large amount of work, the improvement of construction efficiency means that it can be put into use faster, reducing business losses or office inconvenience caused by decoration. The WPC door frame produced by Jiangyin Gwing Technology Co., Ltd. fully considers the ease of installation during the design and production process. The product comes with detailed installation instructions and matching installation accessories to further facilitate the construction and help the construction team complete the installation task efficiently.

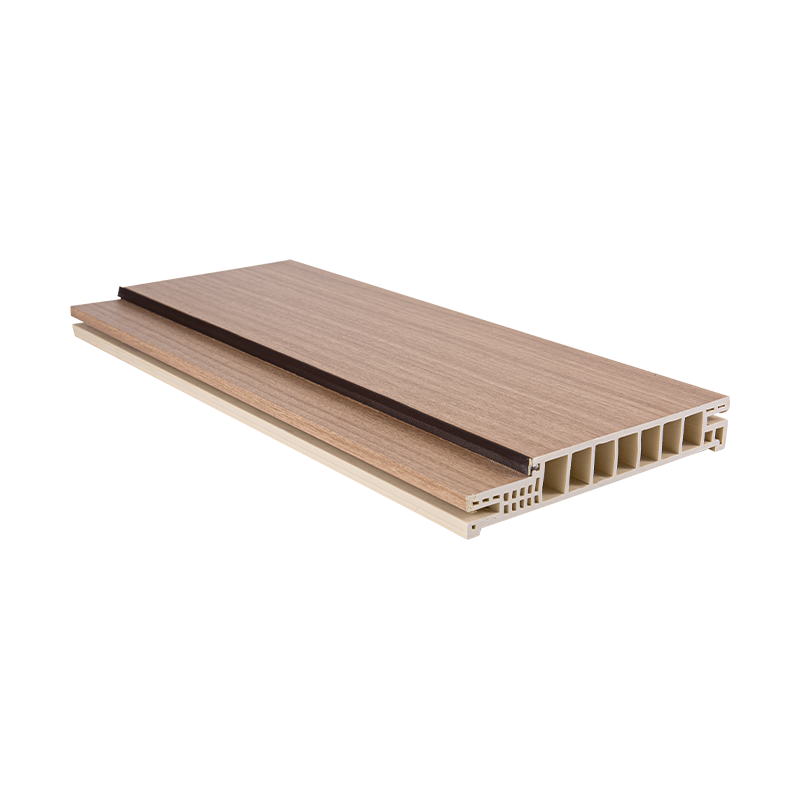

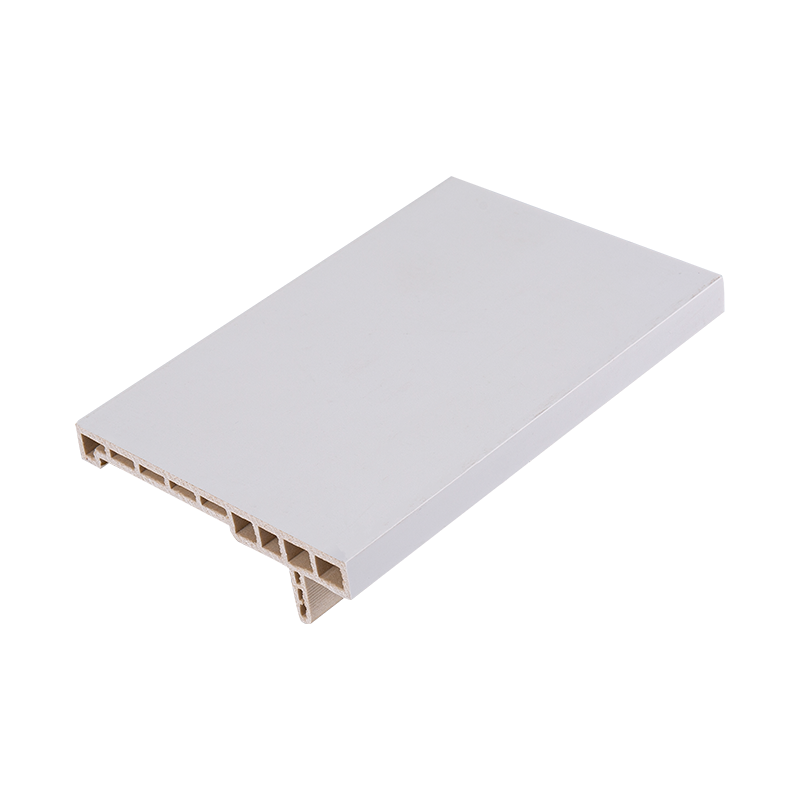

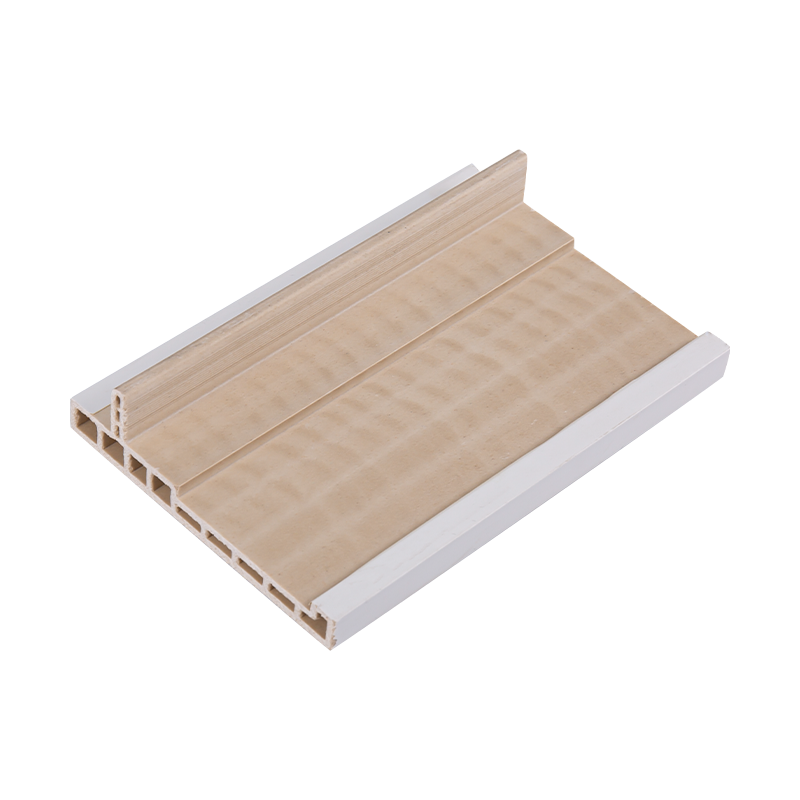

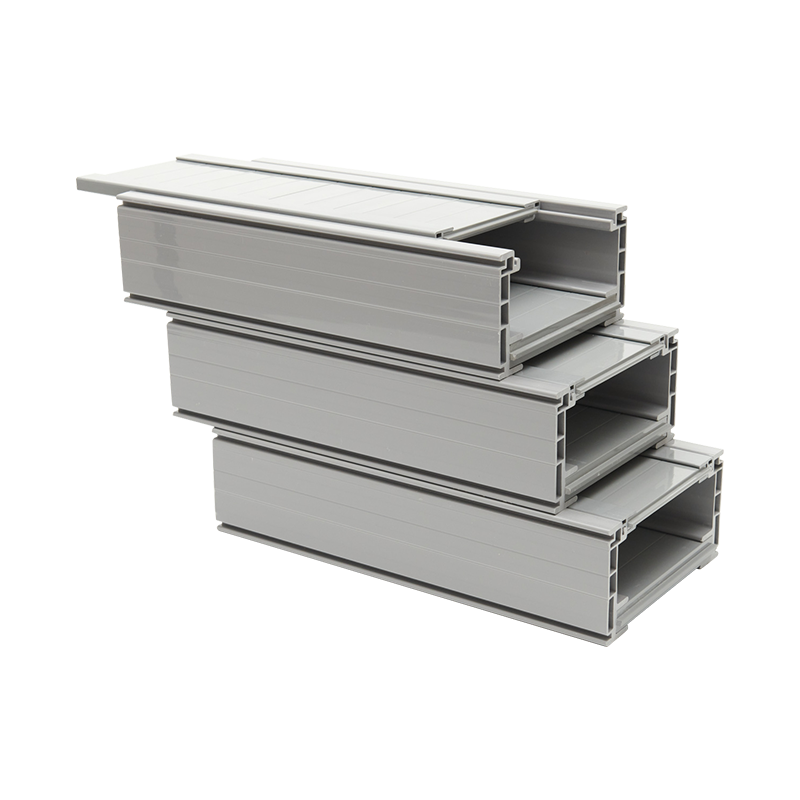

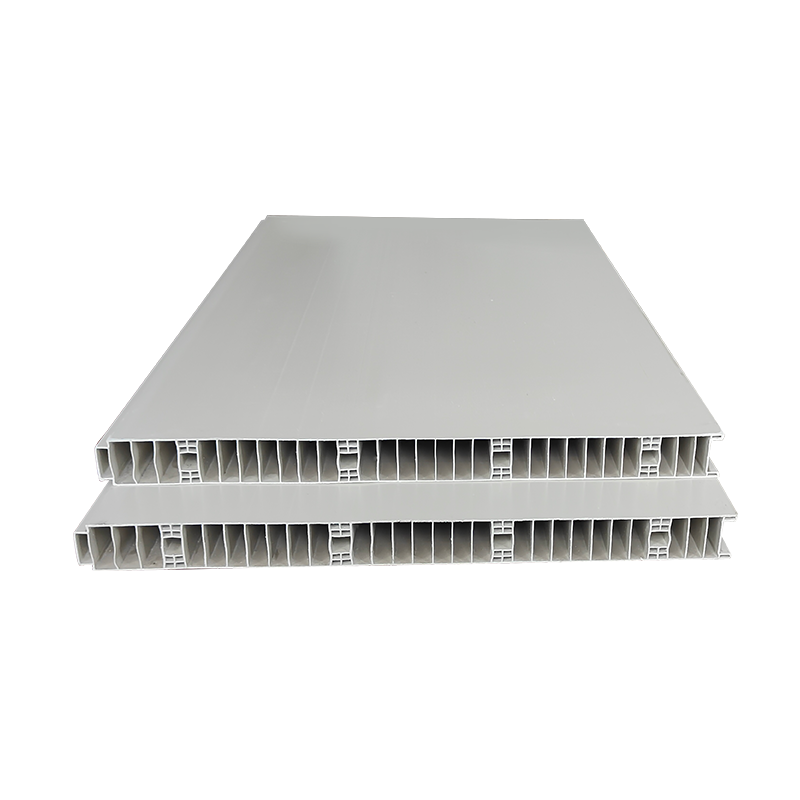

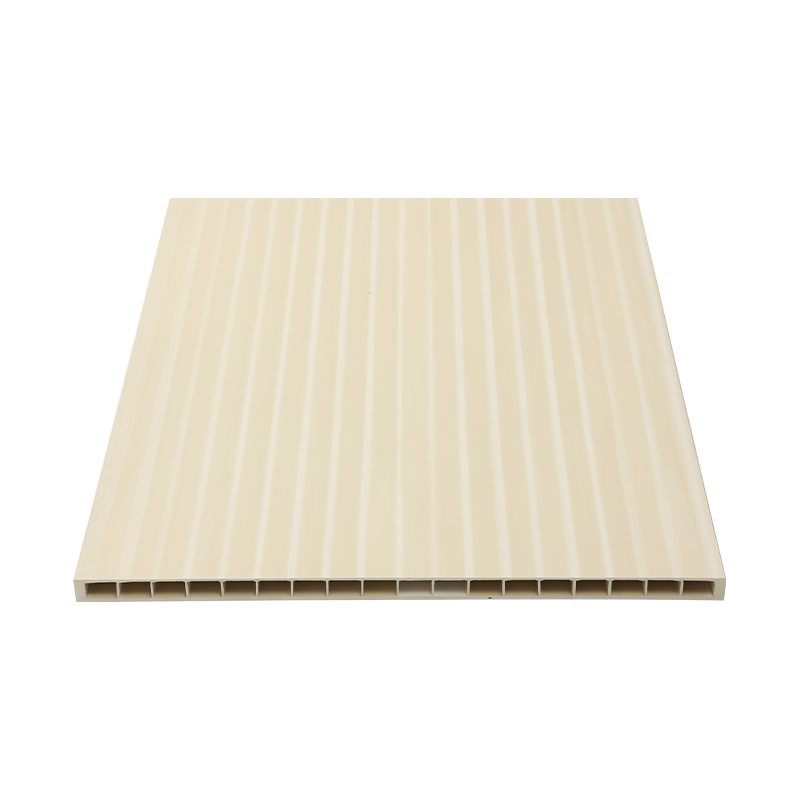

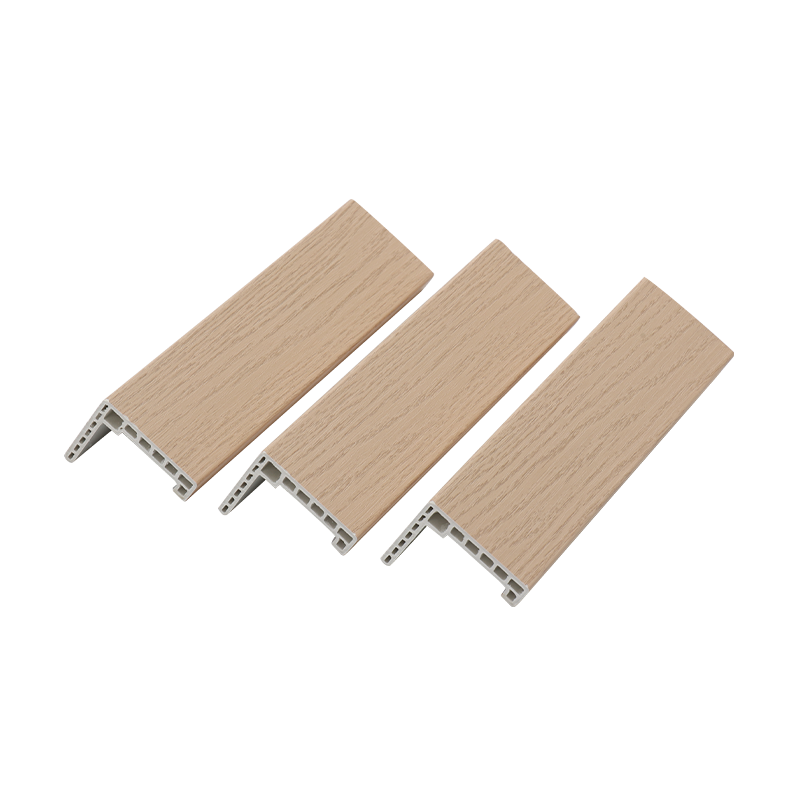

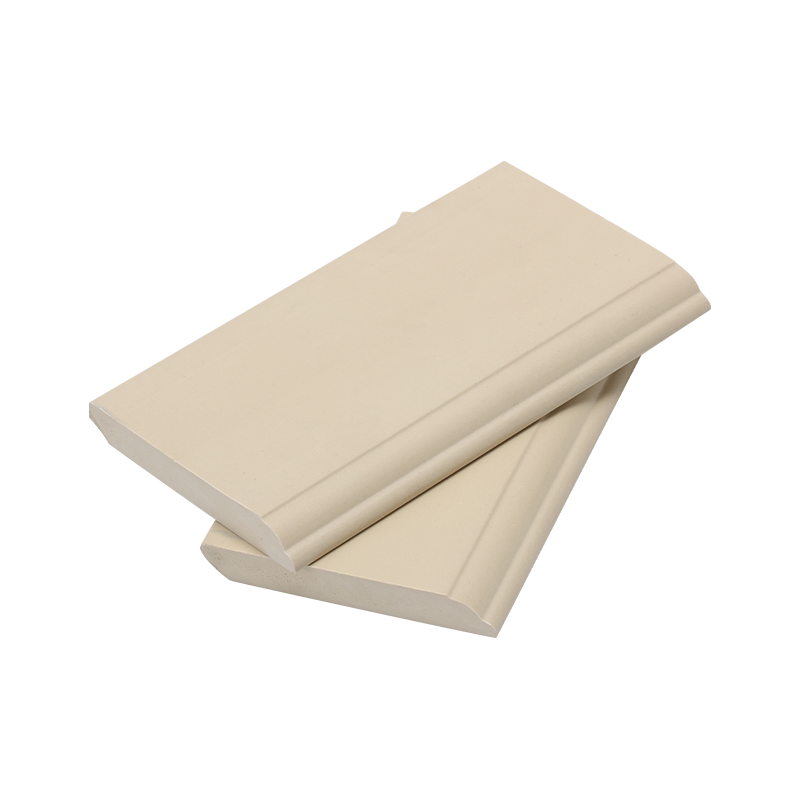

WPC resin door frame is a door frame made of wood plastic composite material (WPC), which combines the advantages of wood and plastic and has unique performance and characteristics. Raw materials: mainly composed of resin, wood fiber and other additives. The door frame has good toughness, waterproofness and corrosion resistance, and the additives further improve its performance, such as improving weather resistance and aging resistance. Production process: usually adopts extrusion molding process, the mixed raw materials are extruded under high temperature and high pressure to form a door frame profile with a specific shape and size. Then after cutting, assembly and other processes, the door line, hardware accessories, etc. are installed to make a complete door frame. Appearance and structure: The appearance of WPC resin door frame usually has a realistic wood grain effect, and a variety of colors and textures can be selected according to different needs to match various decoration styles. Its structural design is reasonable, and the main body of the door frame adopts a hollow or solid core structure, which not only ensures sufficient strength and stability, but also reduces weight, making it easy to install and carry. The edges of the door frame are usually finely processed, with smooth lines, smooth surface, and no burrs and defects.

English

English

English

English عربى

عربى Español

Español