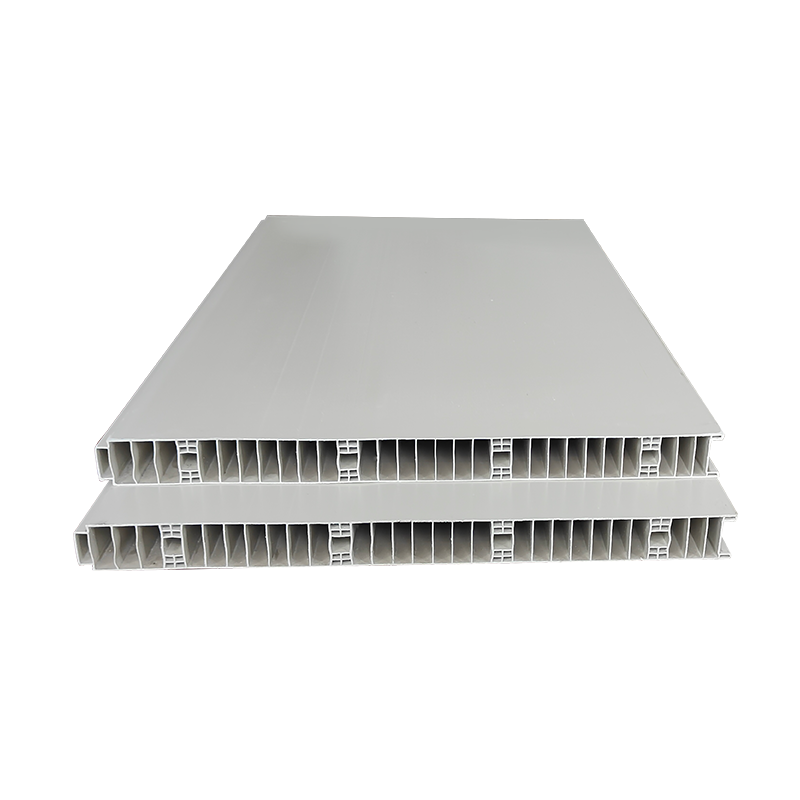

WPC skirting's multi-composite high-quality raw materials

The raw material formula of WPC skirting is the cornerstone of its superior performance, which is mainly composed of wood fiber, thermoplastic plastics and various functional additives. Among them, wood fiber is usually selected from specially treated natural wood fiber. These fibers not only give the product a realistic imitation wood texture, but also improve the strength and toughness of the material to a certain extent, so that WPC skirting has both the natural texture of wood materials and avoids the shortcomings of natural wood being easy to deform. As a key component, the common thermoplastic plastics include polyethylene (PE) and polypropylene (PP). They not only allow the material to show good plasticity during processing, but also give the product excellent waterproofness and flexibility by virtue of their own characteristics. Among them, antioxidants extend the service life of the product, flame retardants improve fire safety, and light stabilizers enhance weather resistance. Jiangyin Gwing Technology Co., Ltd. has established a strict screening mechanism in the raw material procurement link. Each batch of wood fiber is carefully tested, and thermoplastic plastics are also selected from high-quality raw materials to ensure that the product quality is controlled from the source. Combined with advanced mixing technology, each material can play its full role.

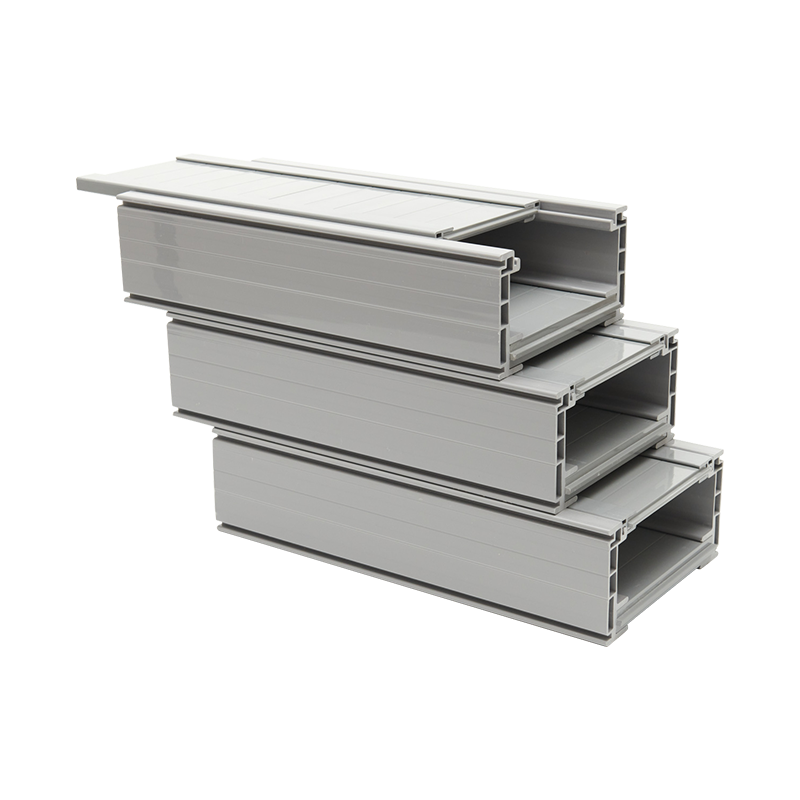

Precise and efficient extrusion molding production process

The production process of WPC skirting usually adopts the extrusion molding process, and every link is crucial. After the wood fiber, thermoplastic plastic and additives are accurately weighed in strict proportion, they are put into a high-speed mixer. Under the action of high temperature and high-speed stirring, various raw materials are fully mixed and plasticized to form a uniform material. These plasticized materials are fed into the extruder. Inside the extruder, the high temperature and high pressure environment causes the material to further melt and extrude through a mold of a specific shape to form a skirting profile with a specific cross-sectional shape and size. At this time, the profile still needs to go through the cooling and shaping stage. Jiangyin Gwing Technology Co., Ltd. uses precision vacuum cooling technology to allow the profile to cool quickly and evenly, ensuring its stable size and smooth surface. The cooled profile is precisely cut according to the actual use requirements, and then the surface treatment processes such as grinding, spraying, and laminating are used to give the product different textures and appearances. Throughout the entire production process, Jiangyin Gwing Technology Co., Ltd. relies on automated production lines and a professional technical team to conduct strict technical quality control at every step, from raw material ratio to finished product output. It also uses online monitoring equipment to monitor production parameters in real time to achieve efficient and stable production.

WPC skirting has excellent and comprehensive practical performance advantages

The advantages of WPC skirting are reflected in multiple dimensions, which can bring consumers a full range of high-quality experience. In terms of waterproofing and moisture-proofing, the dense structure formed by thermoplastics can effectively block the penetration of water vapor on the ground and walls. Environmental protection and health are its highlights. Since natural wood fiber is used as the main raw material and no harmful chemicals such as formaldehyde are added during the production process, it fully complies with national environmental protection standards. For families with elderly people, children and pregnant women, using WPC skirting can safely create a green and environmentally friendly home environment. In terms of durability, its high hardness and strength make it wear-resistant and scratch-resistant. It is difficult to leave obvious marks on its surface due to collisions during daily furniture transportation or scratches by pets, which greatly reduces the probability of product damage and extends its service life. The insect-proof property makes it completely different from the natural wooden skirting, so there is no need to worry about the invasion of termites and other insects, ensuring the stability of the structure and reducing maintenance costs. In terms of installation, WPC skirting is light and easy to carry. The slots or rubber strips designed on the back of the wall make installation very convenient and can be completed in a short time, effectively shortening the decoration period. Its thermal insulation performance can reduce the loss of indoor heat through the corners and help save energy; rich colors and textures can meet the personalized decoration needs of different consumers; and as a recyclable material, it can be recycled after the service life ends, which is in line with the concept of sustainable development.

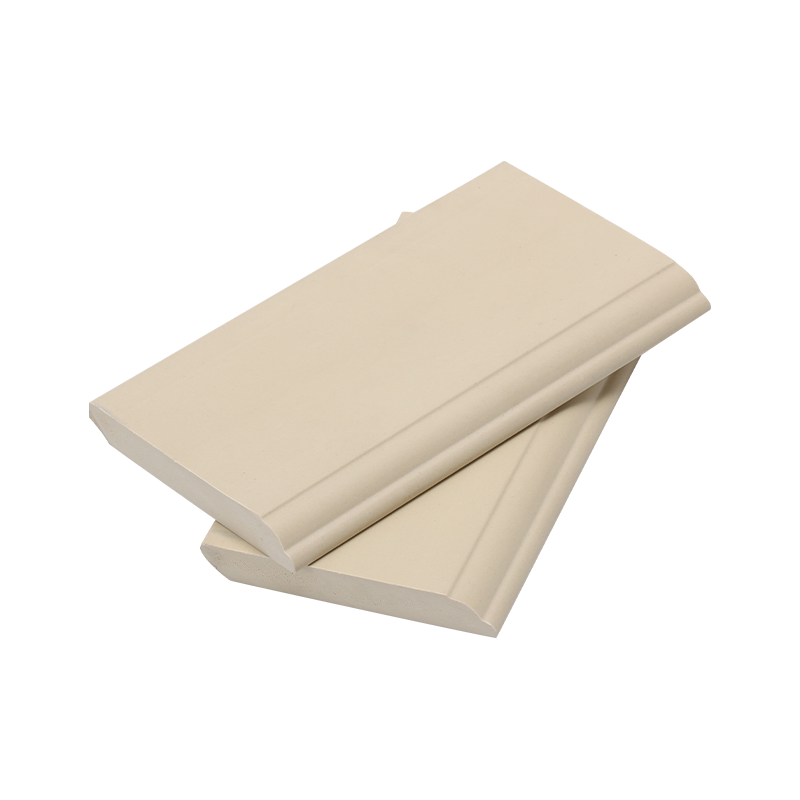

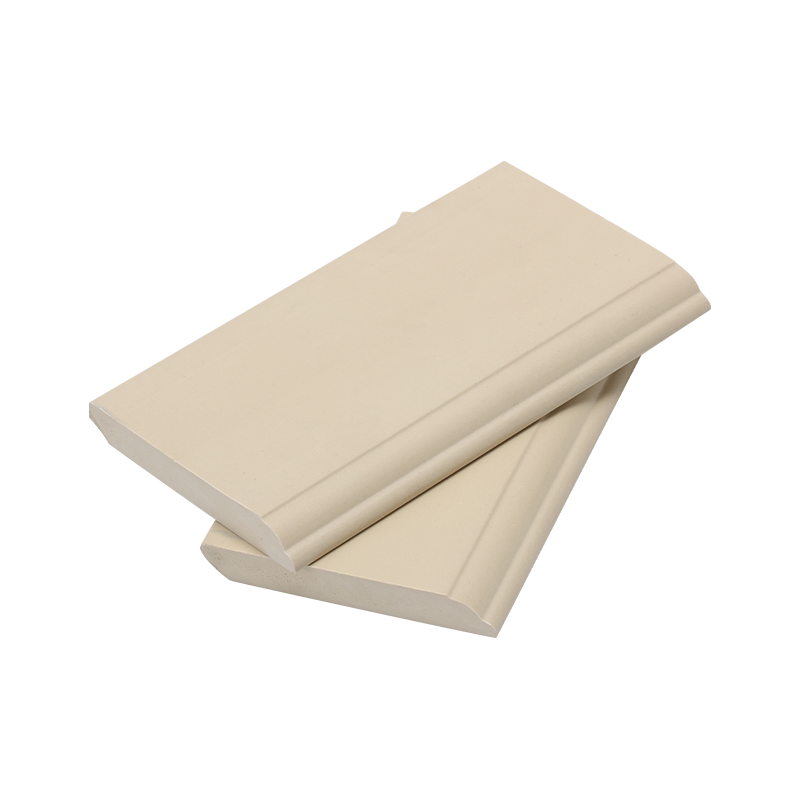

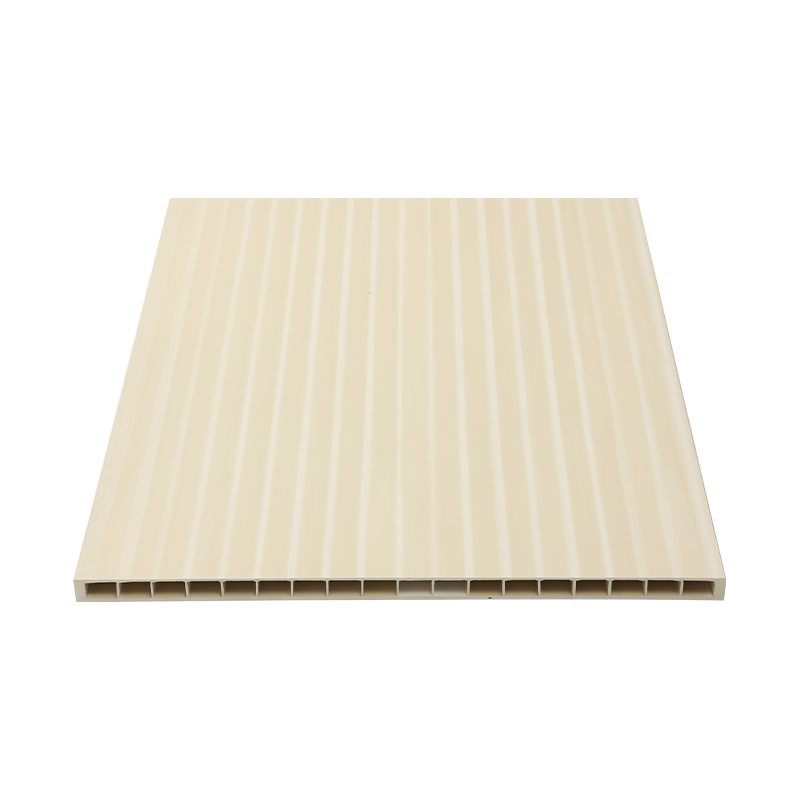

Rich and exquisite diverse appearance design

The diversity of WPC skirting in appearance design comes from advanced surface treatment technology. Through hot pressing, printing, film laminating and other processes, it can realistically simulate the texture and color of various woods, whether it is the simple and elegant walnut grain, the fashionable and atmospheric oak grain, or the luxurious and exquisite marble grain, it can be perfectly presented, easily matching various decoration styles such as modern simplicity, Chinese classical, and European luxury. After special treatment, its surface feels smooth and delicate, with clear and smooth textures and natural and beautiful lines, adding a unique sense of beauty and refinement to the living space. Jiangyin Gwing Technology Co., Ltd. has invested a lot of R&D efforts in appearance design. It uses advanced surface treatment technology to not only provide a rich variety of colors and textures for consumers to choose from, but also adopts a special color curing process to ensure that the color is firmly attached and not easy to fade. Even if it is exposed to sunlight for a long time or undergoes daily cleaning and wiping, WPC skirting can still maintain a bright and new appearance. The company also supports personalized customization services, designing unique textures and colors according to the specific needs of customers.

Raw materials: mainly composed of wood fiber, thermoplastics and various additives. Wood fiber gives it a wood-like texture and a certain strength, thermoplastics give the material good processing performance, waterproofness and flexibility, and additives can improve its weather resistance, flame retardancy and other characteristics, and enhance the overall performance of the product.

Production process: Usually the extrusion molding process is adopted, and the fully mixed and plasticized raw materials are extruded through a specific mold under high temperature and high pressure to form a skirting profile with a specific shape and size. Then, subsequent processing such as cutting and surface treatment is carried out as needed to meet different installation and decoration requirements.

Appearance design: WPC skirting can simulate the texture and color of various woods through surface treatment technology, such as common wood grain, marble, etc., which can match various decoration styles. At the same time, its smooth surface, delicate texture and smooth lines can add beauty and sophistication to the room.

English

English

English

English عربى

عربى Español

Español