WPC Doors: How to become the new favorite in the building materials market?

As building materials are constantly upgraded, a new product called WPC doors is gradually entering the public's field of vision. From home decoration to commercial buildings, the application scenarios of WPC doors are becoming more and more extensive, and their unique performance and advantages have also attracted great attention from both inside and outside the industry.

1. Decoding WPC doors: core advantages from the essence of materials

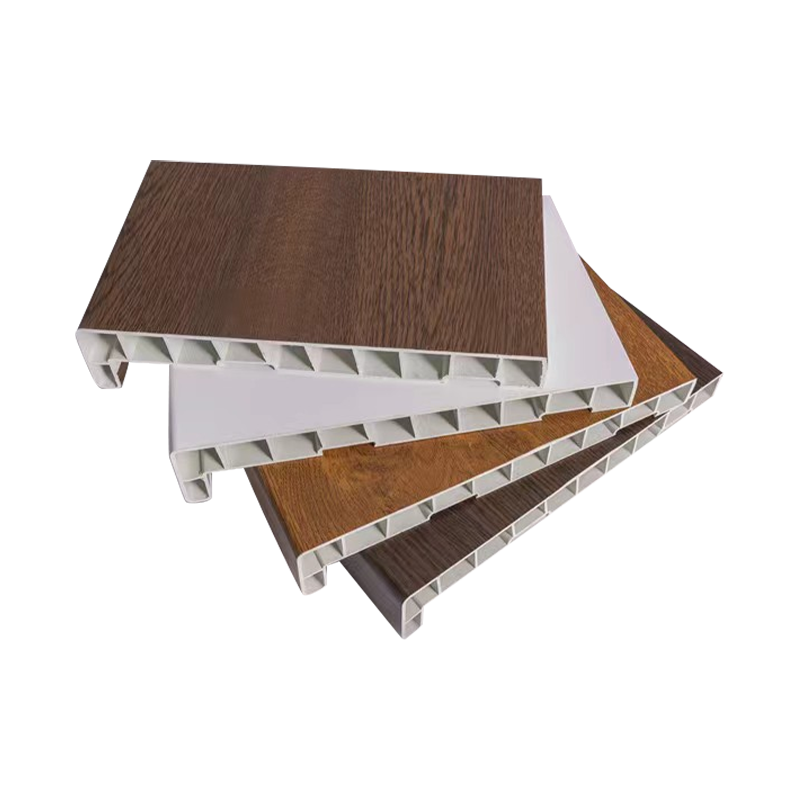

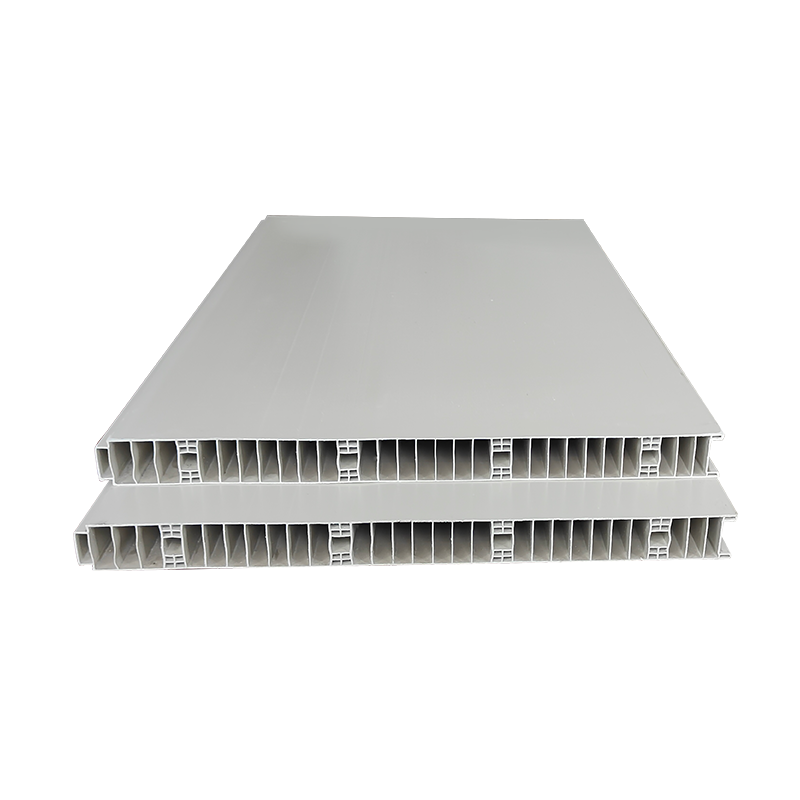

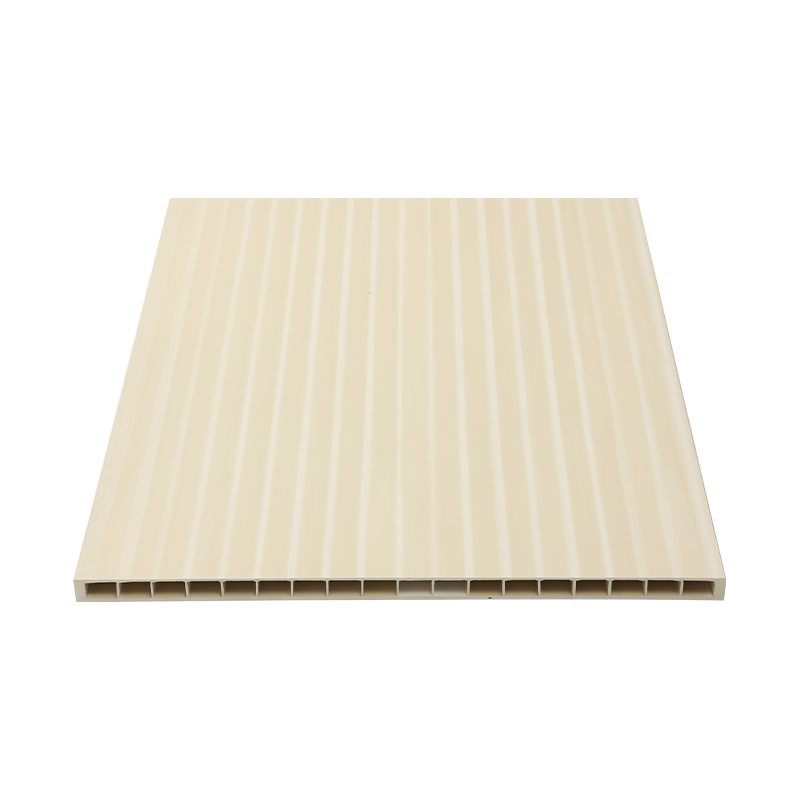

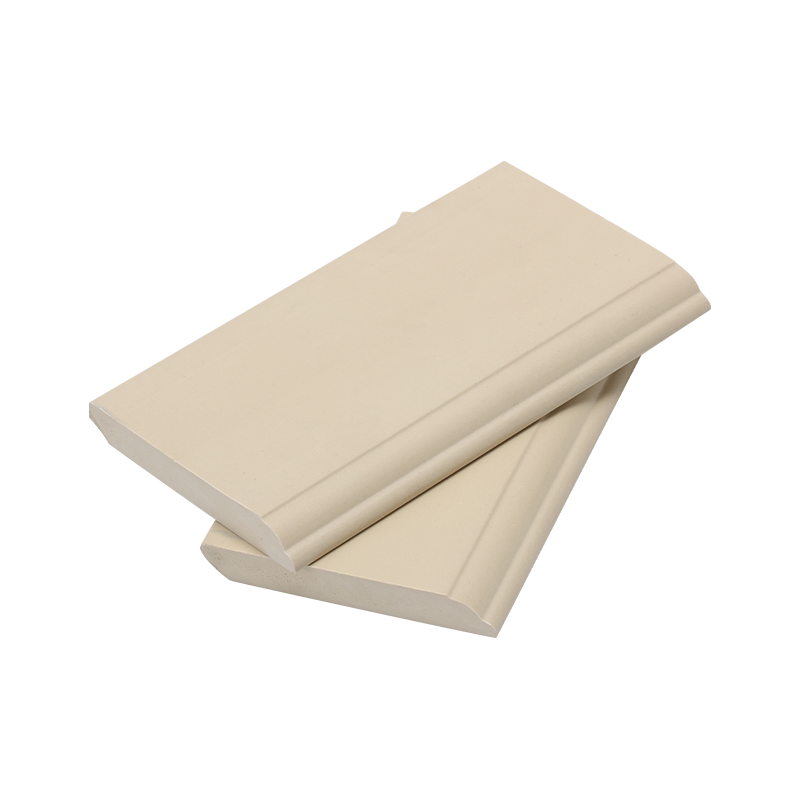

WPC, the abbreviation of Wood-Plastic Composite, means wood-plastic composite materials. WPC doors are door products made of this material as the main raw material. It is made of wood fiber, plastic and a small amount of additives through a special process. It not only retains the natural texture and processing performance of wood, but also integrates the water resistance, moisture resistance and corrosion resistance of plastic. It can be called the "perfect combination" of traditional wooden doors and plastic doors.

Compared with traditional wooden doors, the biggest advantage of WPC doors is their excellent stability. Traditional wooden doors are easily affected by environmental humidity and temperature, causing deformation, cracking and other problems, especially in humid environments such as bathrooms and kitchens, and their service life is greatly reduced. WPC doors contain plastic components, which are difficult for water molecules to penetrate. Even if they are in a humid environment for a long time, they can maintain a stable shape, greatly extending their service life. At the same time, it also has good anti-insect properties, avoiding the trouble of traditional wooden doors being damaged by insects.

Compared with pure plastic doors, WPC doors are more textured and beautiful. It can simulate various wood textures through surface treatment processes, and even achieve a realistic effect to meet the needs of different decoration styles. Moreover, its material is tough and its impact resistance is better than that of ordinary plastic doors. It is more resistant to knocks in daily use and reduces maintenance costs.

2. Technological breakthrough of WPC doors: dual upgrade of environmental protection and performance

With the continuous improvement of global environmental awareness, the environmental protection of building materials has become an important indicator to measure their value, and WPC doors are particularly outstanding in this regard. Among its production raw materials, wood fiber mostly comes from wood processing waste, and plastic can be recycled and regenerated plastic, which realizes the recycling of resources, reduces dependence on natural wood and the pollution of plastic waste to the environment. During the production process, no harmful adhesives such as formaldehyde are needed, which avoids indoor air pollution from the source and meets the requirements of modern homes for green environmental protection.

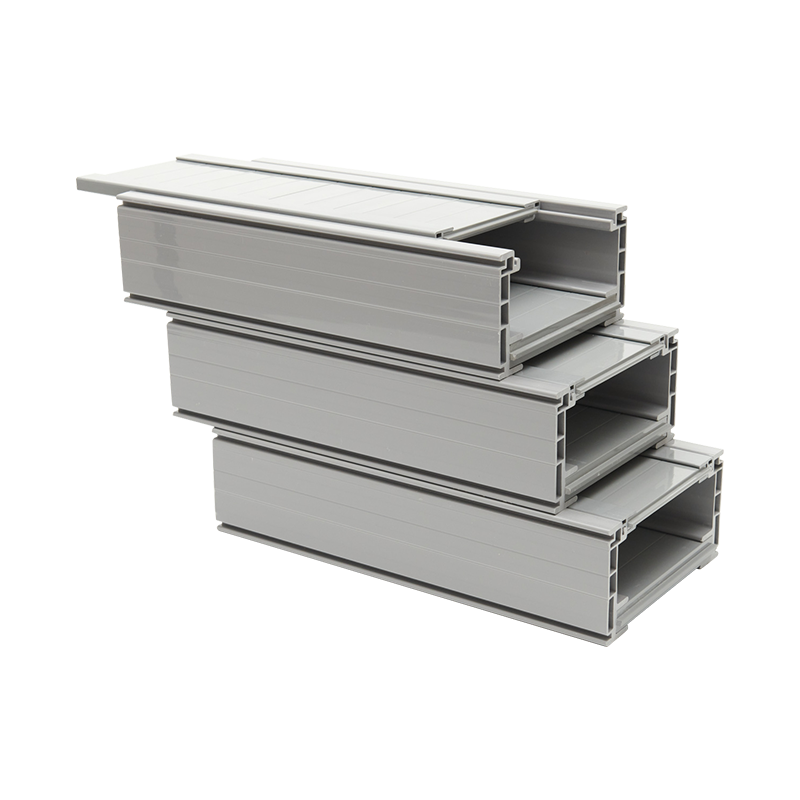

At the technical level, the production process of WPC doors is also constantly innovating. Jiangyin Gwing Technology Co., Ltd., as a technology-driven enterprise focusing on the field of polymer composite materials, has always adhered to the concept of environmental protection and is committed to the research and development and production of WPC doors and polymer composite products. With nearly 20 years of technical accumulation, the WPC doors it has developed have been continuously optimized in terms of material ratio and molding process, so that the products have achieved breakthroughs in strength, toughness, weather resistance and other performance. For example, by adjusting the ratio of wood fiber and plastic and combining advanced extrusion molding technology, the WPC doors produced are not only lighter and easier to install, but also have higher structural strength and can better adapt to the needs of different building scenes.

3. Market prospects of WPC doors: application scenarios and development potential

Today, the application of WPC doors is no longer limited to a single field, but has emerged in multiple scenarios with its diversified advantages. In home decoration, it is suitable for wet areas such as bathrooms, kitchens, and balconies, and can also be used in dry spaces such as bedrooms and living rooms to achieve a unified style for the doors of the whole house. In commercial buildings, hotels, hospitals, schools and other places have high requirements for the durability and easy cleaning of doors. WPC doors are ideal choices because of their moisture-proof, anti-fouling and easy-to-care characteristics.

From the perspective of market development trends, with the increase in consumers' environmental awareness and the improvement of product performance requirements, the market demand for WPC doors is expected to continue to grow. On the one hand, the country's increasingly stringent environmental protection standards for building materials have provide

d policy support for the promotion of WPC doors; on the other hand, companies like Jiangyin Gwing Technology Co., Ltd. continue to invest in research and development to promote innovation in WPC doors in style design, function expansion, etc., such as developing products with additional functions such as sound insulation and fire prevention, further enriching the product system and enhancing market competitiveness.

With its multiple advantages such as environmental protection, durability, and beauty, as well as continuously improving technical support, WPC doors are gradually becoming the new darling of the building materials market. It not only meets the demand for high-quality materials in modern architecture, but also conforms to the trend of the times of green and sustainable development.

English

English

English

English عربى

عربى Español

Español